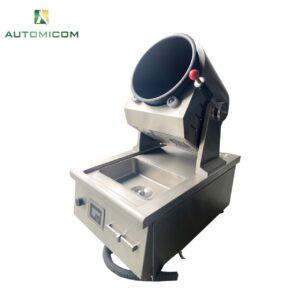

Horizontal Continuous Vacuum Band Sealer (ASS99)

$3,932.00

- Thicker and wider heating block & cooling block to ensure the quick and perfect sealing. High precision processed driving wheel, much beautiful.

- High-quality solid rubber tensioning knob, wearproof. Unibody gear box, flank fixed, more steady.

- High-quality polyformaldehyde gear with high- strength injection molding, Running more smooth and low noise. Patent to replace the sealing belt, which is easy and convenient. Shield on the machine to ensure the safety of the operator. Conveyor can be easily adjusted up, down, ahead or back according to the size of the products.

- Elegant panel, easy operation, variable speed conveyor. Can with the gas filling ,the filling time is adjustable. The new choice of the vacuum pump to ensure the high degree of vacuum. AirTac” filter can prevent the products (such as small granule ,liquid ) into the vacuum pump.

SPECIFICATION

| Power supply |

110V,220-240V/50-60HZ 1 Phase

|

| Power consumption | 875W |

| Sealing speed | 0-12m/min |

| Sealing width | 6-12mm |

| Max single layer film thickness | ≤0.08mm |

| Temperature range | 0-300℃ |

| Printing letters |

1 lines 15 letters (Solid ink printer)

|

| Max conveyor loading | 5KG |

| Machine size |

1025*450*(940+140 adjustable)mm

|

| Machine weight | 85KG |

FEATURES

Thicker and wider heating block & cooling block to ensure the quick and perfect sealing. High precision processed driving wheel, much beautiful. Suitable for sealing all kinds of heat sealed packaging bags like aluminium foil bag, Kraft bag, PE, Shrink film and so on. Widely use for food, pharmaceutical industry, chemical industry, lubricating oil and so forth.

High-quality solid rubber tensioning knob, wearproof. Unibody gear box, flank fixed, more steady.

Heating and cooling fine copper block

High-quality polyformaldehyde gear with high- strength injection molding, Running more smooth and low noise. Patent to replace the sealing belt, which is easy and convenient. Shield on the machine to ensure the safety of the operator. Conveyor can be easily adjusted up, down, ahead or back according to the size of the products.

Elegant panel, easy operation, variable speed conveyor. Can with the gas filling ,the filling time is adjustable. The new choice of the vacuum pump to ensure the high degree of vacuum. AirTac” filter can prevent the products (such as small granule ,liquid ) into the vacuum pump.

Security guarantee, strict protection design. Emergency stop switch, in case of emergency, it can be shut down directly, and the safety is guaranteed

Reviews

There are no reviews yet.