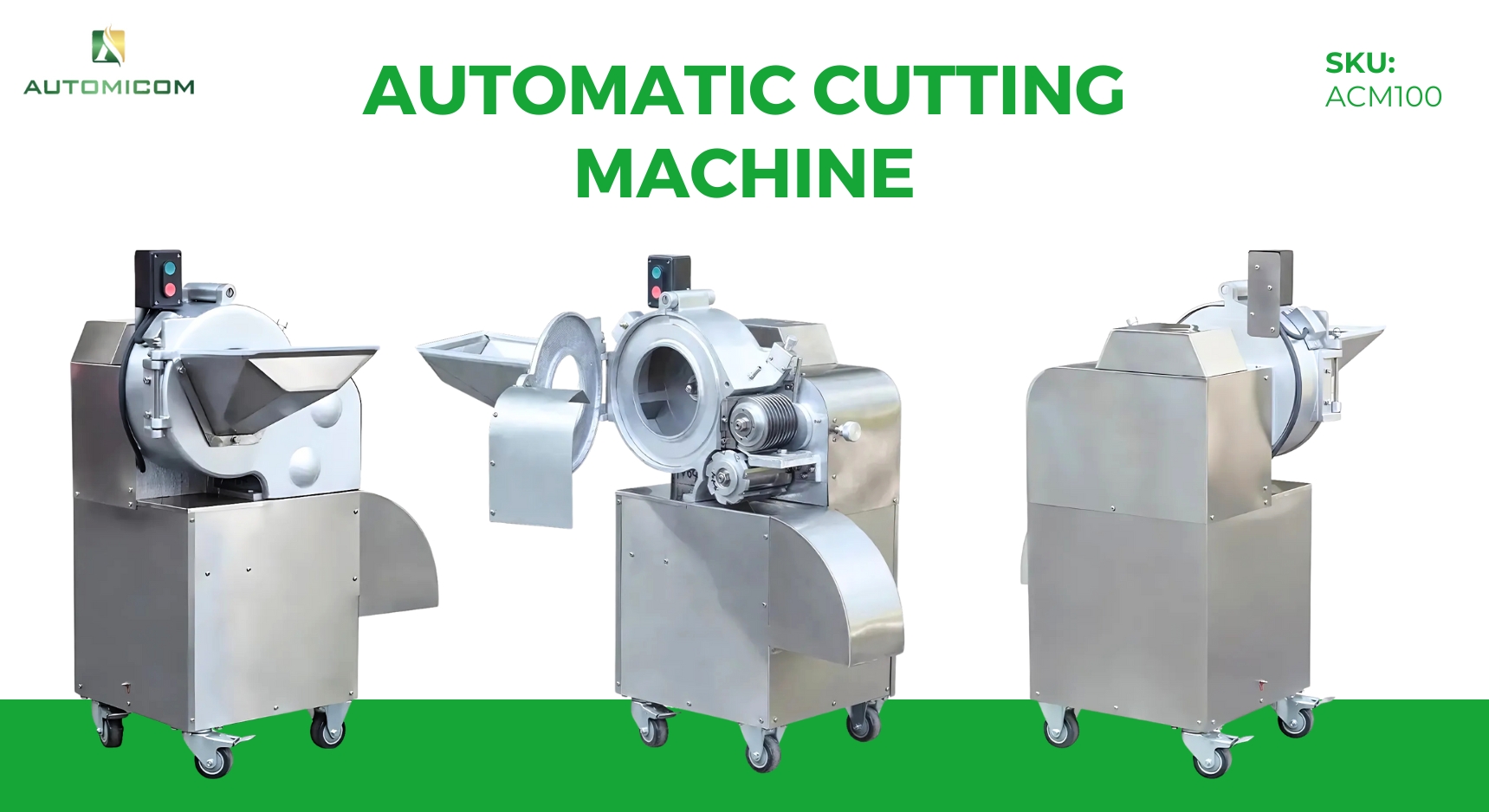

Automatic Cutting Machine (ACM100)

$4,500.00

- Fast and Precise Cutting – Ensures uniform cuts, reducing waste and boosting productivity.

- Durable Stainless Steel – Provides long-lasting performance and easy cleaning.

- Large Inlet Feeder – Handles bigger food items for efficient processing.

- Easy Mobility – Includes sturdy wheels with a lockable anti-slip system.

- Versatile Use – Cuts meats, vegetables, and fruits for various industries.

INTRODUCTION OF AUTOMATIC CUTTING MACHINE

An Automatic Cutting Machine is a high-precision device that streamlines the cutting process across various industries. Therefore, this advanced equipment enhances productivity by eliminating manual labor, ensuring accuracy, and reducing material waste. Whether used in metalworking, textiles, packaging, or food processing, an Industrial Cutting Machine consistently delivers efficient results.

Specifically, our Automatic Cutting Machine dices meat, vegetables, and root vegetables with precision and efficiency. Moreover, the machine features sharp blades, high-speed operation, and high-quality stainless steel construction, making it ideal for factory use. As a result, it significantly reduces manpower while ensuring consistent cutting results. Additionally, its durable construction and reliable performance make it a must-have for food processing businesses looking to enhance productivity and maintain high hygiene standards.

Furthermore, an Automatic Cutting Machine operates with minimal human intervention due to its state-of-the-art technology. Consequently, the efficiency of an Industrial Cutting Machine makes it perfect for mass production, improving workflow and minimizing errors. In addition, modern Industrial Cutting Machines include user-friendly interfaces, automated settings, and safety features, ensuring seamless operation.

Ultimately, investing in an Automatic Cutting Machine is a strategic decision for industries aiming to boost efficiency and maintain high-quality standards. With precision, speed, and reliability, an Industrial Cutting Machine remains an indispensable tool for businesses looking to enhance their manufacturing capabilities.

SPECIFICATIONS

| Model | ACM100 |

| Voltage | 380V |

| Power | 1.5kw |

| Yield | 800-1000kg/h |

| Cutting specifications | 4-15mm Customizable( standard:5*5/10*10) |

| Product size | 710*640*990mm |

| Product weight | ≈90kg |

KEY FEATURES OF AUTOMATIC CUTTING MACHINE

- Durable Stainless Steel Build

The machine features a high-quality stainless steel body, ensuring strength and corrosion resistance. Moreover, its sturdy construction enhances durability, allowing continuous operation in demanding environments.

- Large Inlet Feeder

The spacious inlet feeder accommodates larger food items, reducing the need for pre-cutting. As a result, it saves time and labor while boosting productivity by processing a higher volume of ingredients.

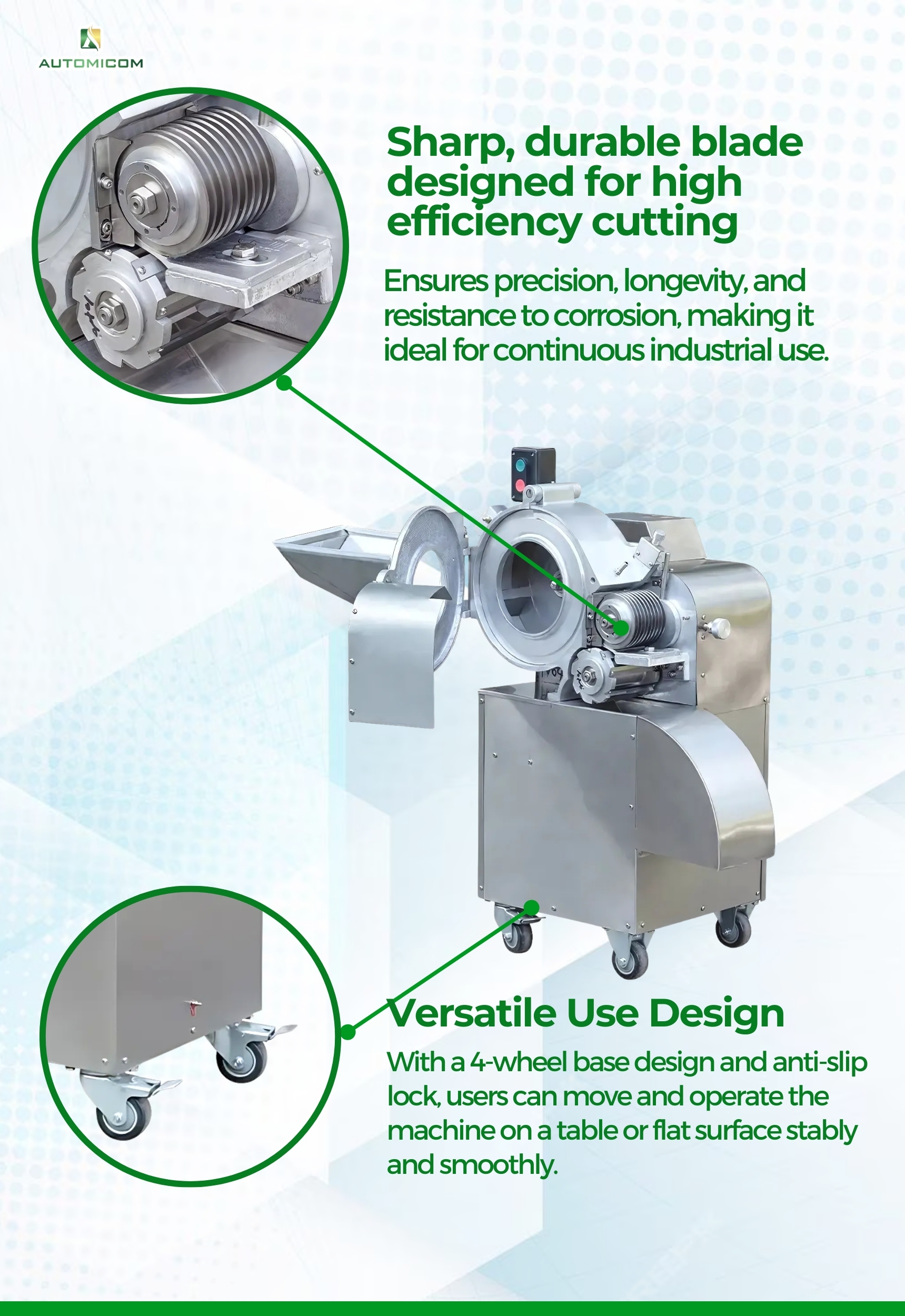

- Easy Mobility

The sturdy wheels enable smooth movement across the workspace for added convenience. Moreover, the lockable anti-slip feature ensures stability, preventing unwanted shifts during operation.

- High-Efficiency Cutting Blade

The sharp and durable blade delivers precise, uniform cuts, minimizing food waste. Additionally, its high-speed cutting mechanism enhances efficiency, allowing faster processing without sacrificing accuracy.

- Hygienic and User-Friendly Design

The smooth, easy-to-clean surface maintains hygiene and reduces downtime. Furthermore, the user-friendly interface simplifies operation, making it accessible for all skill levels.

CLOSER LOOK

APPLICATIONS OF AUTOMATIC CUTTING MACHINE

Meat Processing Industry

The Automatic Cutting Machine plays a crucial role in the meat processing industry by efficiently cutting beef, pork, chicken, and fish into uniform pieces. Consequently, it enhances productivity in butcher shops, meat factories, and frozen food processing plants. Moreover, it reduces manual labor and ensures precise cuts, allowing businesses to meet high production demands.

Vegetable and Fruit Processing

This machine efficiently slices, dices, and chops various vegetables and fruits. As a result, it improves efficiency in salad production, frozen food processing, and canned food manufacturing. Furthermore, it maintains consistency in size and shape, ensuring better presentation and quality for packaged products.

Food Packaging and Ready-to-Eat Meals

Food processing facilities rely on this machine to prepare ingredients for packaged meals and pre-cut food products. Therefore, it significantly boosts efficiency in catering services, meal prep businesses, and food service industries. Additionally, it streamlines production and reduces preparation time, helping businesses serve customers faster.

Catering and Restaurant Industry

Restaurants and catering businesses depend on the Automatic Cutting Machine to handle large volumes of food preparation. Consequently, it ensures uniform cuts, speeds up meal prep, and maintains food safety standards. Moreover, it helps chefs focus on cooking rather than time-consuming cutting tasks, making it essential for high-demand kitchens.

Frozen and Processed Food Manufacturing

This machine cuts meats, vegetables, and other ingredients before freezing or further processing. As a result, it enhances production efficiency and maintains product consistency. Additionally, it helps manufacturers meet quality standards by ensuring precise cuts that improve cooking and packaging processes.

1 year warranty

1. What types of food can the Automatic Cutting Machine process?

The machine efficiently cuts a variety of foods, including meats, vegetables, root vegetables, and fruits. Additionally, it works well for frozen and processed food items, making it ideal for diverse food industries.

2. How does the machine improve efficiency in food processing?

By automating the cutting process, the machine significantly reduces manual labor and speeds up production. Moreover, its precise cutting mechanism ensures uniform pieces, minimizing waste and enhancing overall productivity.

3. Is the machine easy to clean and maintain?

Yes, the machine features a smooth stainless steel surface that allows quick and easy cleaning. Furthermore, its user-friendly design simplifies maintenance, ensuring hygiene and long-term durability.

4. Can the machine be moved easily within the workspace?

Yes, the machine is equipped with sturdy wheels for smooth mobility. Additionally, the lockable anti-slip feature ensures stability during operation, providing both flexibility and safety.

5. What safety features does the machine have?

The machine includes safety locks, stable operation controls, and an anti-slip base to prevent accidents. Moreover, its enclosed cutting mechanism minimizes the risk of injuries, ensuring safe use in busy work environments.

Reviews

There are no reviews yet.