Industrial Vertical Band Seal (BS1000)

$4,900.00

- High-Speed Sealing – Boosts productivity in fast-paced packaging lines.

- Vertical Design – Ideal for sealing upright, heavy, or spill-prone bags.

- Adjustable Settings – Customize temperature and speed for different materials.

- Durable Construction – Built with 304 stainless steel for strength and hygiene.

- User-Friendly Operation – Simple controls and low maintenance for daily use.

INTRODUCTION OF INDUSTRIAL VERTICAL BAND SEALER

To begin with, the Industrial Vertical Band Seal offers a powerful and efficient packaging solution that seals a wide range of bags and pouches in an upright position. In addition, this machine serves industries that handle granular, powdered, or liquid products, providing a reliable way to maintain product freshness and safety. As a result, businesses can ensure quality control throughout the packaging process. Moreover, the Industrial Vertical Band Sealer, designed for high-volume operations, delivers consistent sealing results with adjustable temperature and speed settings. Consequently, users can optimize performance across various packaging materials with ease and precision. On the other hand, many professionals refer to this machine as a Vertical Continuous Band Sealer, especially in the food, chemical, pharmaceutical, and agricultural sectors. Notably, its vertical design easily seals heavier or spill-prone items while minimizing mess and waste.

Furthermore, the Vertical Continuous Band Sealer includes a conveyor system that enables continuous sealing, boosts productivity, and reduces labor demands. Equally important, its durable construction, user-friendly controls, and low maintenance needs make the Industrial Vertical Band Sealer an excellent choice for businesses aiming to streamline their packaging operations. Whether you’re working with plastic, laminated, or aluminum foil bags, the Vertical Continuous Band Sealer delivers airtight, secure closures every time. Ultimately, thanks to its efficient performance and versatility, this machine adds significant value to any industrial packaging line.

SPECIFICATIONS

| Model | CBS-1900V |

| Power supply | 220V/50HZ |

| Sealing speed | 0-12m/min |

| Power | 1200W |

| Sealing width | 5-10mm |

| Temperature control range | 0-300 ℃ |

| Sealing film thickness | 0.02-0.08mm |

| Transport load | ≤ 40kg |

| Machine size | 1100 * 610 * 1030mm |

| Machine weight | 200KG |

| Number of printed characters | ≤ 20 per row (double row ink wheel printing) |

| Adjustable sealing height | 180-1100mm |

| Steel casing | |

| Sealing width 10mm | |

| Rocker Switch | |

| Steel gear | |

| Slow speed of 12 meters per minute | |

| Digital display | |

| Maximum bag height 1100mm | |

| Sealed pocket height 40mm | |

| The maximum height of the machine head is 630mm | |

| Head extension | |

| Load capacity 50KG | |

| Assist roller length 400mm

Dual heating+heat dissipation |

|

| Motor model 6R250W | |

KEY FEATURES OF INDUSTRIAL VERTICAL BAND SEALER

-

High-Quality Design

The Industrial Vertical Band Sealer features a rugged structure built with 304 food-grade stainless steel. This premium material resists corrosion, supports hygiene standards, and simplifies cleaning. Its heavy-duty frame withstands continuous use in demanding environments. Operators can count on its long-lasting durability and consistent sealing performance. -

User-Friendly Control Panel

The machine includes a straightforward, clearly labeled control panel that simplifies operation. Operators can quickly adjust sealing temperature, speed, and pressure without confusion. This streamlined interface boosts productivity, reduces training time, and eliminates common handling errors. -

Servo Motor Drive

The powerful servo motor ensures smooth, precise, and efficient operation. It delivers accurate control over sealing speed, minimizes vibrations, and extends the machine’s life. By using servo technology, the sealer consumes less energy and offers quieter, more stable performance.

-

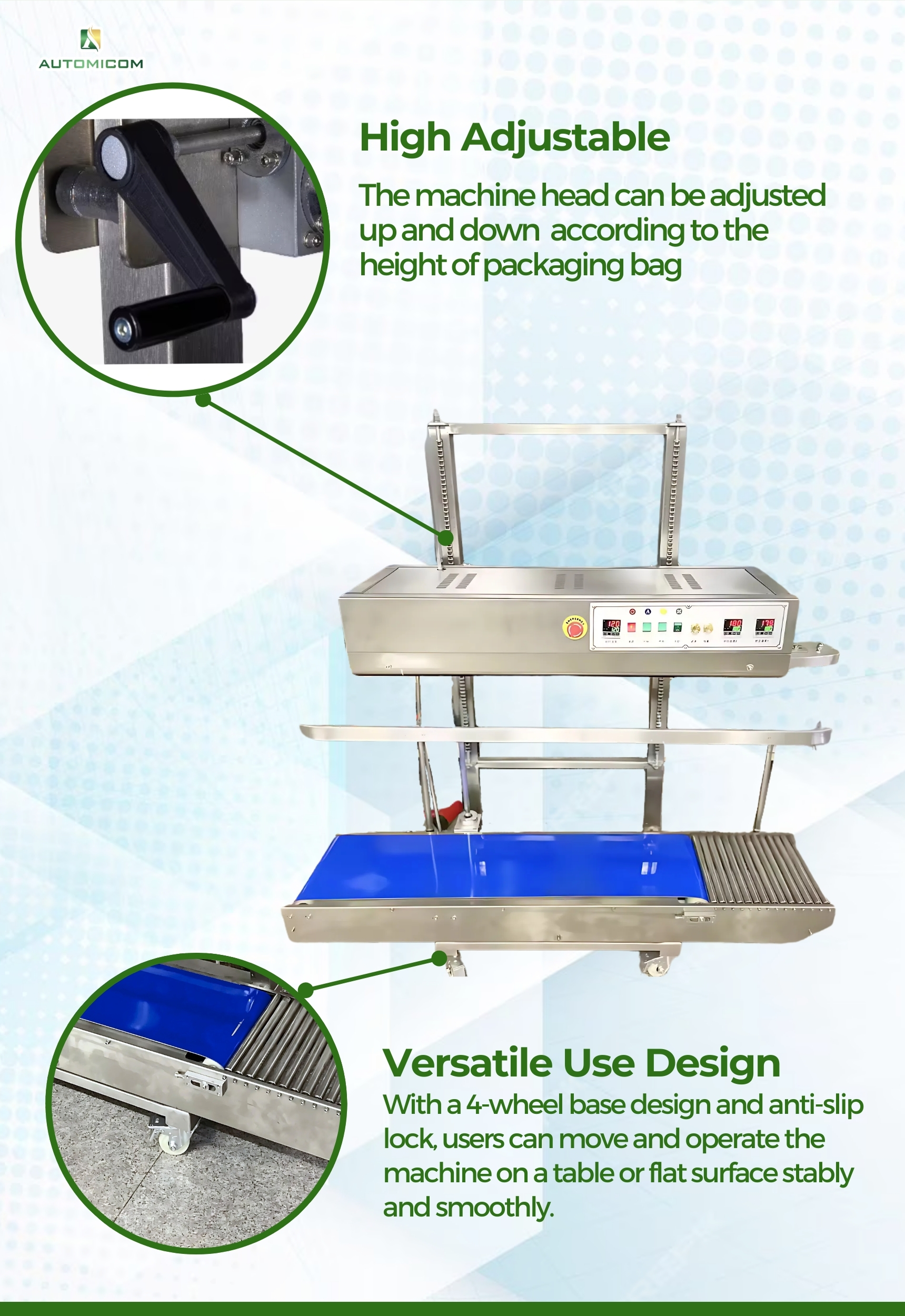

Height Adjustable Design

Users can easily adjust the height of the sealing head and conveyor to match various bag sizes. This flexibility allows efficient sealing of both small and large pouches, especially those containing liquids or heavy materials. -

Versatile Use Design

The Industrial Vertical Band Sealer handles multiple bag types and materials. Manufacturers across food, chemical, agricultural, and pharmaceutical industries use it to seal plastic, laminated, and foil packaging with precision and speed.

CLOSER LOOK

APPLICATIONS OF INDUSTRIAL VERTICAL BAND SEALER

-

Food Packaging

To begin with, food manufacturers rely on the Industrial Vertical Band Sealer to seal a wide range of products including rice, beans, coffee, powdered milk, spices, snacks, and sauces. In particular, the vertical design helps workers seal upright bags easily, especially when handling liquid or granular products. As a result, this sealing method locks in freshness, improves shelf life, and maintains hygiene standards throughout the packaging process. -

Pharmaceutical Products

Additionally, pharmaceutical companies use the machine to seal tablets, capsules, herbal powders, and nutritional supplements. With full control over temperature and speed, operators adjust settings to meet the demands of sensitive medical packaging. Consequently, the machine ensures clean, secure closures without contamination, supporting a sterile and reliable workflow. -

Agricultural Goods

Moreover, seed producers, fertilizer suppliers, and animal feed manufacturers benefit from the sealer’s ability to handle large, heavy-duty pouches. Because of the adjustable design, workers can easily adapt the sealing height and conveyor to suit different bag sizes. Therefore, the machine becomes an excellent fit for bulk agricultural operations. -

Chemical and Industrial Materials

Similarly, chemical plants use the sealer to package detergents, powdered chemicals, and fine particles in laminated or foil pouches. Thanks to its corrosion-resistant stainless steel body, the machine handles harsh environments while maintaining consistent performance. As a result, teams operate more safely and efficiently. -

Liquid and Semi-Liquid Packaging

Finally, producers of sauces, oils, gels, and cosmetic creams benefit from the vertical sealing system, which prevents spills during packaging. In turn, this design allows operators to seal liquid-filled pouches confidently and cleanly, minimizing mess and product waste.

1 year warranty

-

What types of packaging materials can the Industrial Vertical Band Sealer handle?

The machine handles a wide variety of materials including plastic, laminated film, aluminum foil, and kraft paper bags. It seals pouches used in food, pharmaceuticals, chemicals, and agriculture industries with consistent, high-quality results. -

Can I adjust the sealing speed and temperature?

Yes, the Industrial Vertical Band Sealer features an adjustable control panel that allows users to set the sealing speed and temperature according to the type and thickness of the bag material. This ensures optimal sealing for every application. -

What is the maximum bag weight or size the machine can seal?

The machine typically supports bags up to 10 kg, depending on the specific model and conveyor strength. Its height-adjustable design accommodates various pouch sizes, making it suitable for both small and large packaging needs. -

Is the machine easy to maintain and operate?

Absolutely. The machine includes a user-friendly interface, minimal wear components, and a stainless steel body that’s easy to clean. Routine maintenance only requires basic checks and cleaning, allowing operators to keep the machine running smoothly with minimal downtime.

Reviews

There are no reviews yet.