Automatic container sealer (TS59)

$8,500.00

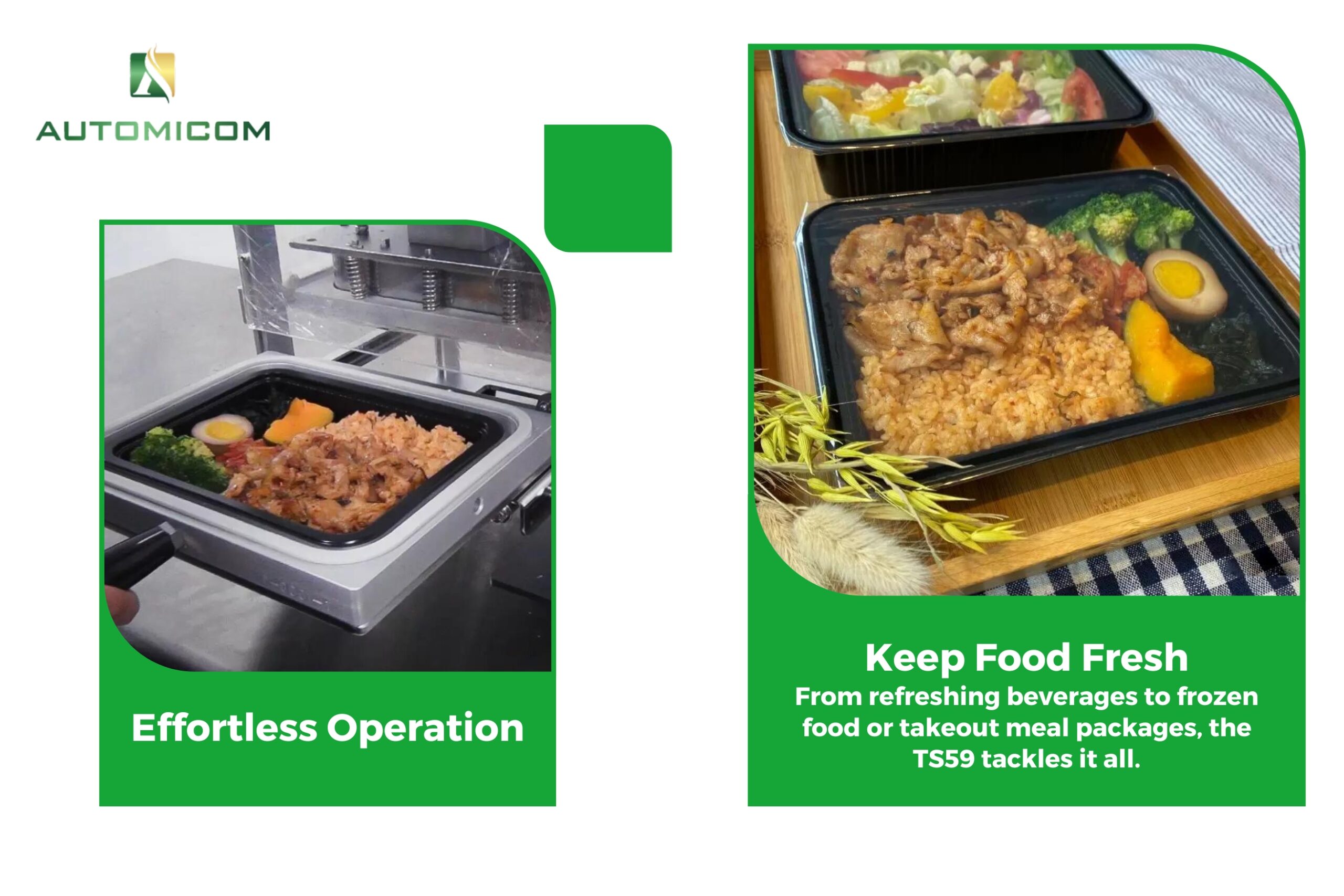

- Versatile Sealing: Handles various tray sizes with replaceable moulds.

- Airtight Packaging: Ensures secure seals to maintain freshness.

- Compact Design: Ideal for small spaces and efficient use.

- User-Friendly: Easy to operate with intuitive controls.

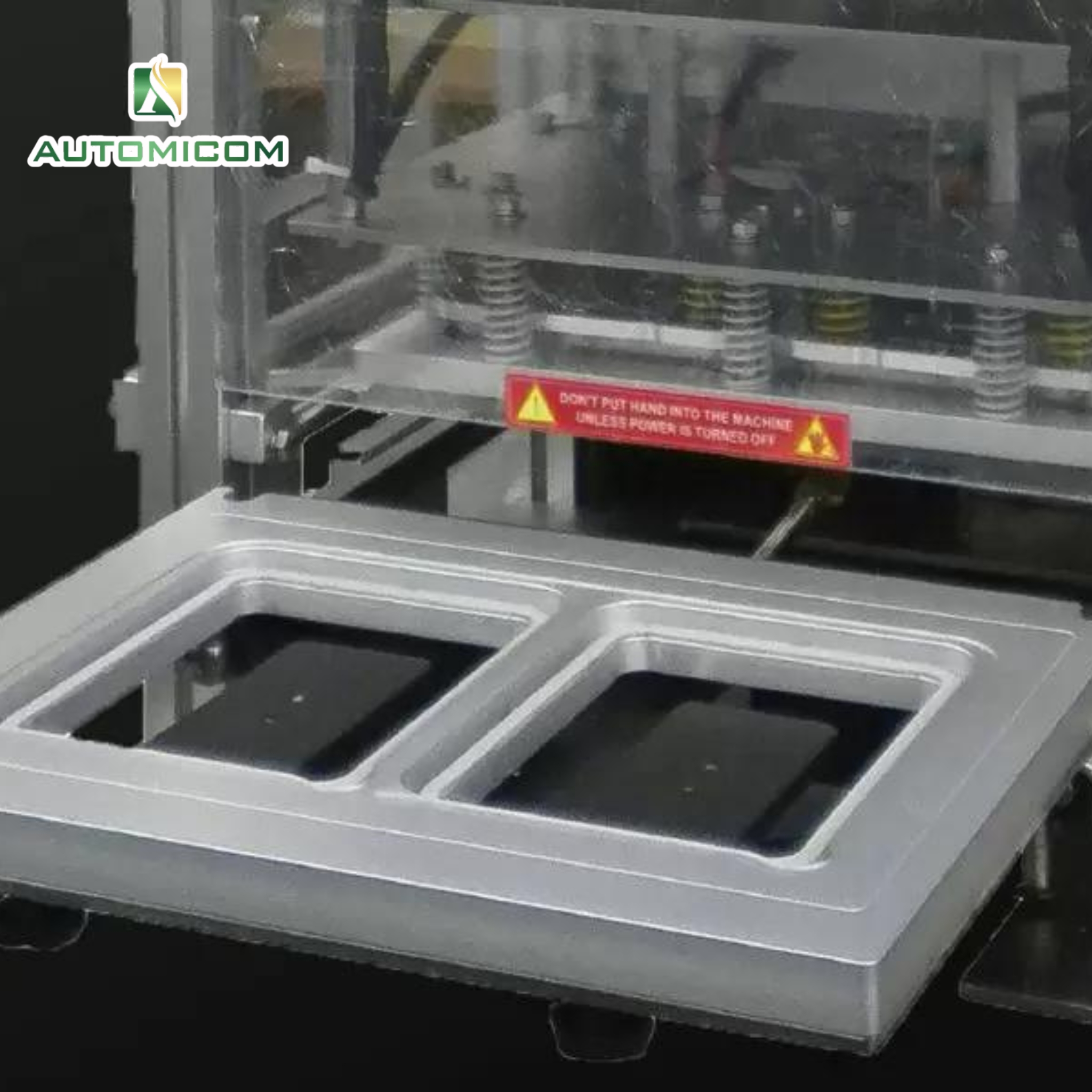

- Efficient: Supports multiple cavities for faster production.

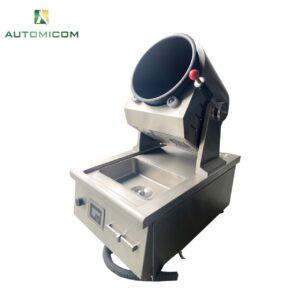

The automatic tray sealer (TS59) is a versatile and efficient packaging solution widely used in the food industry. Specifically, it is designed to seal various types of trays securely, ensuring freshness and hygiene in the packaging process. Moreover, one of the key features of this machine is its replaceable mould, which allows users to work with different tray sizes, making it adaptable for a variety of products. In addition, this flexibility enables the machine to handle multiple cavities, increasing productivity by sealing several trays at once. Consequently, the automatic container sealer (TS59) is particularly suitable for small to medium-sized production lines that require reliable and consistent sealing.

With user-friendly controls, the automatic container sealer (TS59) offers precision and ease of use, making it a valuable tool for businesses looking to streamline their packaging process. Its compact design is ideal for companies with limited space, and the machine’s efficiency helps reduce labour costs. Additionally, the ability to quickly change moulds allows for seamless transitions between different packaging requirements, minimizing downtime. This sealing system also ensures that the trays are tightly sealed, preventing contamination and extending the shelf life of the products.

Specification for automatic container sealer TS59

| Model | TS59 |

|---|---|

| Machine Size | 420 x 540 x 770 mm |

| Power | 110/220V, 600W |

| Production Capacity | 400 Seals/hr |

| Max. Container Size | 220 x 170 x 120 mm |

| Weight | 60kg |

| Case | Stainless steel |

| Date/Code Printer | Applicable |

Key features of container sealer TS59

- Mould Replaceable: The machine’s mould is replaceable, allowing use with different tray sizes for versatile packaging. It supports multiple cavities for higher efficiency.

- Compact Design: Its tabletop size is perfect for small spaces, offering efficient packaging without taking up much room.

- Easy Operation: User-friendly controls simplify the sealing process, making it accessible even for beginners in packaging.

- Quick Tray Changeover: The machine allows for fast and easy tray size changes, minimizing downtime and improving workflow efficiency.

- Secure Sealing: It provides airtight sealing for trays, ensuring product freshness and preventing contamination during storage.

- Energy Efficient: Designed with low energy consumption in mind, this tray sealer operates efficiently to reduce operational costs.

- Durable Construction: Built with high-quality materials, the machine ensures long-lasting performance, even in demanding production environments.

Application of TS59

- Food Packaging: Ideal for sealing ready-to-eat meals, fresh produce, and snacks in trays to preserve freshness.

- Meat and Poultry: Used in sealing trays for raw or processed meats, ensuring hygiene and extended shelf life.

- Dairy Products: Suitable for packaging cheeses, yogurts, and other dairy items to maintain their quality and prevent contamination.

- Bakery Items: Perfect for sealing baked goods such as pastries and cakes, keeping them fresh for longer periods.

- Seafood Packaging: Ensures secure, airtight sealing of fish and seafood, maintaining freshness and reducing spoilage.

For larger tray sizes, the automatic tray sealer (pneumatic type) offers an efficient solution. Alternatively, the semi-automatic tray sealer is a great option for medium-scale operations, providing flexibility and ease of use. Meanwhile, the manual tray sealer is ideal for smaller-scale needs, offering simplicity and precision without sacrificing quality.

| Automatic tray sealer | TS59 |

|---|

The tray sealer comes with a 1-year warranty, excluding the heating element and cutter, which are durable parts.

- What types of trays can the automatic tray sealer handle? The automatic tray sealer can handle various tray sizes due to its replaceable moulds. It supports different tray dimensions and multiple cavities for versatile packaging needs.

- How easy is it to change the moulds on this machine? Changing the moulds is straightforward and quick, allowing for seamless transitions between different tray sizes. This feature minimizes downtime and enhances operational efficiency.

- What are the benefits of using this automatic tray sealer for packaging? This machine provides airtight seals to preserve product freshness and prevent contamination. Its compact design, energy efficiency, and user-friendly controls make it a valuable addition to small to medium-sized production lines.

Reviews

There are no reviews yet.