Industrial Food Chopper

- Interchangeable Blades: Customize chopping styles for different ingredients.

- High Capacity: Processes large volumes quickly and efficiently.

- Safety Mechanisms: Includes automatic shut-off features for user protection.

- Food-Grade Materials: Made of stainless steel for hygiene and durability.

- Intuitive Controls: Easy adjustments for speed and chopping time.

INTRODUCTION OF INDUSTRIAL FOOD CHOPPER

The Industrial Food Chopper serves as a vital tool for large-scale food preparation, specifically designed to meet the high demands of commercial kitchens and food processing facilities. Moreover, like a Vegetable Chopper Machine, this powerful device excels at cutting, dicing, and slicing a wide variety of ingredients, which makes it essential for both chefs and food processors alike.

Constructed from durable stainless steel, the Vegetable Chopper Machine not only delivers long-lasting performance but also maintains high hygiene standards critical for food safety. Additionally, its robust motor allows users to handle large volumes of vegetables and other ingredients quickly and uniformly, ensuring consistent results every time. As a result, this efficiency significantly enhances overall kitchen productivity.

By streamlining food preparation processes, the Industrial Food Chopper effectively reduces labor costs and minimizes preparation time, enabling kitchens to maintain high productivity levels even during peak hours. Furthermore, its versatility allows users to create consistent cuts for a wide range of dishes, including salads, soups, sauces, and various culinary creations. Consequently, this ensures that every dish meets the desired quality and presentation standards, which is essential in the competitive food service industry.

Whether used on machine’s its own or integrated into broader food processing systems, the Industrial Food Chopper stands out as an essential piece of equipment for modern culinary operations. Ultimately, its ability to adapt to different food preparation needs makes it an indispensable tool for anyone in the food industry looking to enhance efficiency and quality in their kitchen.

SPECIFICATIONS

| Model of industrial food chopper | IFC32 |

IFC50 |

| Voltage | 110/220V | 380V/50Hz |

| Power | 1.5kW | 4500W |

| Productivity of Vegetable Chopper Machine | 800-1000 kg/hour | 100-300kg per hour |

| Capacity of Vegetable Chopper Machine | 32L | 50L |

| Product size | 670*620*1050mm | 740*790*1120mm |

| Product weight | ≈ 35kg | ≈71kg |

KEY FEATURES

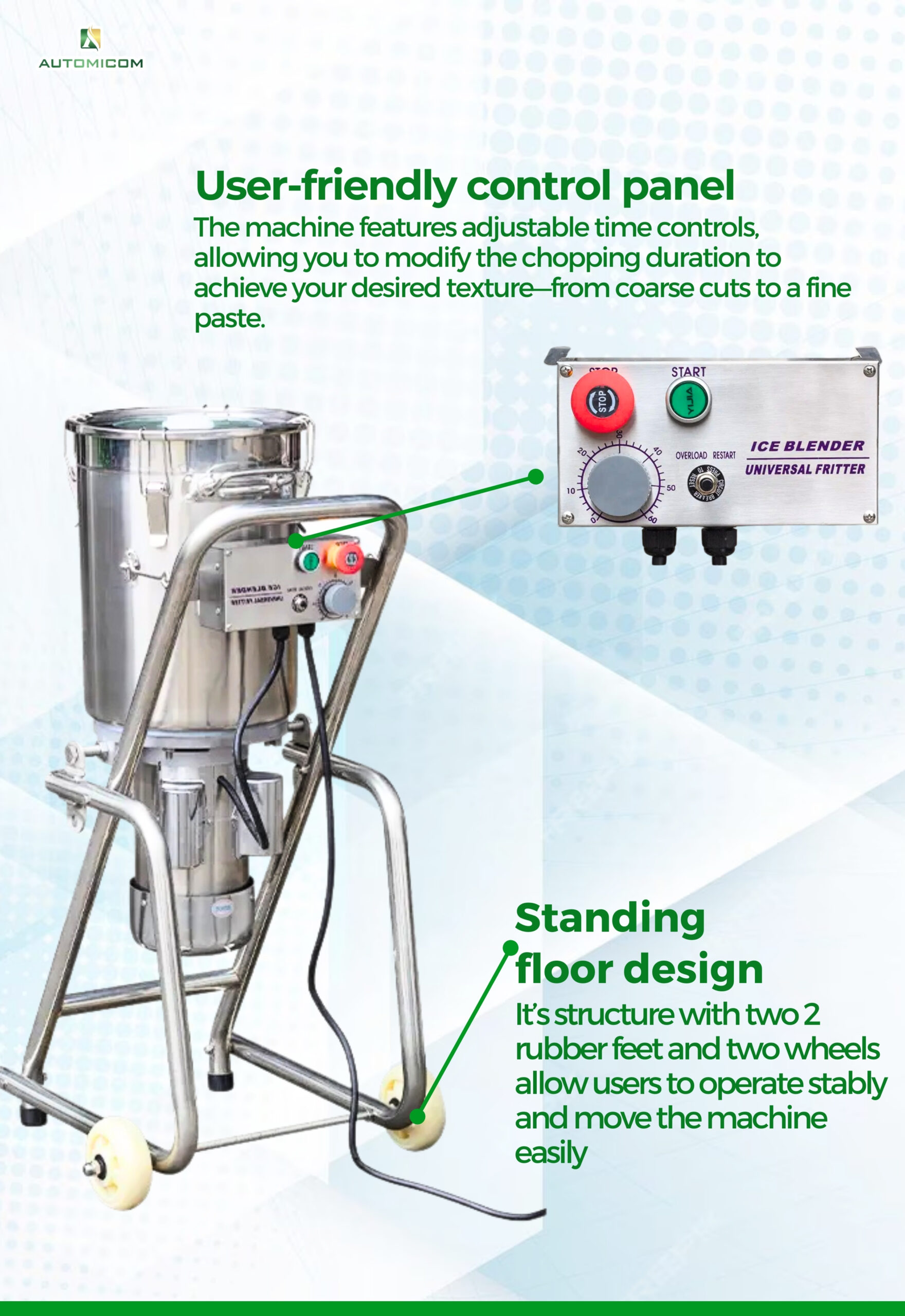

The user-friendly control panel simplifies operation, making Vegetable Chopper Machine accessible for all users. In addition, the machine features adjustable time controls, allowing you to modify the chopping duration easily. As a result, you can achieve your desired texture, ranging from coarse cuts to a fine paste.

Moreover, the precision-engineered stainless steel blades are designed for efficient and uniform chopping. These blades maintain their sharpness over extended use, which ensures clean cuts and optimal performance. Whether you are processing vegetables, meat, or other food products, the blades of Vegetable Chopper Machine deliver consistent results.

Furthermore, the high-performance 4500W motor delivers exceptional chopping power and speed, significantly enhancing productivity in your kitchen. Additionally, Vegetable Chopper Machineoperates at 380V, providing the necessary power for demanding tasks.

Finally, the Industrial Food Chopper is made from food-grade stainless steel, which guarantees maximum food safety and hygiene standards. This feature ensures that your food preparation remains safe and meets all regulatory requirements.

CLOSER LOOK OF INDUSTRIAL FOOD CHOPPER

- Multi-Functional Design: Industrial food choppers feature interchangeable blades, allowing users to customize chopping styles for various ingredients. This versatility helps chefs achieve finely minced garlic or thick vegetable slices.

- High Throughput Capacity: These industrial food choppers can process large quantities of ingredients quickly. Some models chop hundreds of kilograms of vegetables per hour, ideal for high-volume production.

- Safety Features: Additionally, industrial food choppers include essential safety mechanisms, such as automatic shut-off features. This ensures the machine stops when the lid is open or components are improperly positioned.

- Hygienic Materials: Importantly, these machines are constructed with food-grade stainless steel, resisting corrosion and facilitating easy cleaning. Consequently, they help maintain high hygiene standards and comply with food safety regulations.

- User-Centric Control Panels: Many models come equipped with intuitive control panels, allowing users to adjust settings easily. Thus, this design ensures optimal results with minimal effort, enhancing food preparation efficiency.

APPLICATIONS OF INDUSTRIAL FOOD CHOPPER

- Large-Scale Vegetable Preparation: The industrial food chopper quickly chops, dices, and slices large quantities of vegetables for various dishes. Thus, this efficiency enhances menu offerings and speeds up food service operations.

- Food Processing and Manufacturing: This machine prepares ingredients for soups, sauces, and packaged meals in food processing plants. Moreover, it ensures consistent cuts, improving product quality and overall efficiency.

- Frozen Food Production: The industrial food chopper efficiently chops vegetables and proteins for pre-cooked frozen meals. Consequently, this process helps maintain freshness and flavor in the final products.

- Catering and Event Services: Catering companies use the industrial food chopper for quick, uniform preparation of large ingredient quantities. As a result, it allows teams to meet tight deadlines with high-quality dishes.

- Deli and Salad Bars: In delis and salad bars, the industrial food chopper creates fresh, ready-to-eat salads and prepared foods. Therefore, it enhances variety and effectively meets customer dietary needs.

| Industrial Food Chopper | IFC32, IFC50 |

|---|

1 year warranty

- What types of ingredients can the industrial food chopper process?

The industrial food chopper can efficiently process a wide range of ingredients, including vegetables, fruits, meats, and herbs, making it versatile for various food preparation tasks. - How do I clean and maintain the industrial food chopper?

Most industrial food choppers feature removable parts that allow for easy cleaning. Regular maintenance, such as lubricating moving parts and ensuring the blades remain sharp, helps maintain optimal performance. - What is the production capacity of the industrial food chopper?

The production capacity varies by model, but many industrial food choppers can handle hundreds of kilograms of ingredients per hour, making them suitable for high-volume food preparation.

Reviews

There are no reviews yet.