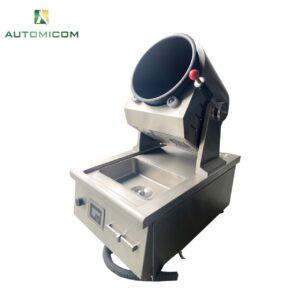

Semi Industrial Dehydrator (DH6/DH10/DH16/DH32)

- Precise Temperature – Adjustable 30°C-90°C for optimal drying.

- Multiple Sizes – Available in 6, 12, 16, and 32 trays.

- Long Operation – Runs up to 10 hours continuously.

- Versatile Use – Dries fruits, meats, herbs, and pet treats.

- Energy Efficient – Intelligent control system reduces power consumption.

INTRODUCTION OF SEMI INDUSTRIAL DEHYDRATOR

Introducing Automicom Semi Industrial Dehydrator, It provides an efficient and reliable solution for drying various foods while maintaining their nutrients and flavors. Therefore, it meets the needs of businesses requiring more capacity than household dehydrators but less than full-scale industrial units. Moreover, this Mid Scale Dehydrator balances performance and affordability, making it ideal for small food processing businesses, farms, and commercial kitchens.

Additionally, the Semi Industrial Dehydrator uses advanced airflow technology to distribute heat evenly, preventing moisture buildup and ensuring uniform drying. Furthermore, its adjustable temperature settings allow precise control over different food types, improving preservation quality. Since this Mid Scale Dehydrator operates with energy efficiency, it reduces costs while maximizing output.

Similarly, the Semi Industrial Dehydrator features a durable stainless steel body, ensuring long-lasting performance and easy maintenance. Its spacious multi-tray design increases drying capacity, allowing businesses to process more food efficiently. In addition, the Mid Scale Dehydrator includes a user-friendly interface, simplifying operation and reducing labor time.

Whether for small-scale food production, organic farming, or commercial kitchens, the Semi Industrial Dehydrator boosts efficiency and convenience. As a result, businesses using the Mid Scale Dehydrator extend shelf life and reduce food waste effortlessly.

SPECIFICATIONS OF SEMI INDUSTRIAL DEHYDRATOR

|

Model |

DH06 | DH10 | DH16 | DH32 |

| Voltage | 220V | 220V | 220V | 220V |

| Power consumption | 500W | 800W | 1500W | 3000W |

| Temperature range | 30-120C | |||

| Machine size | 34.5 x 28.7 x 39.5 cm | 34.5 x 42.7 x 38.5 cm | 47 x 67 x 57 cm | 46.8 x 138 x 57 cm |

| Chamber size | 31 x 21 x 28 cm | 31 x 35 x 28 cm | 42 x 60 x 38.5 cm | 38.5 x 60 x 41.4 cm |

| Machine weight | 7.8kg | 10.6kg | 22.5kg | 46KG |

| Machine body material | SS201 | |||

| Tray material | SS304 | |||

| Number of trays | 6 | 10 | 16 |

32 |

| Mesh size | 30 x 28cm, mesh size 0.8 x 0.8 cm, and the spacing between upper and lower layers is 3.5cm | 30 x 28cm, mesh size 0.8 x 0.8 cm, and the spacing between upper and lower layers is 3.5cm

|

40 x 38cm, mesh size 0.8 x 0.8 cm, and the spacing between upper and lower layers is 3.5cm

|

40 x 38cm, mesh size 0.8 x 0.8 cm, and the spacing between upper and lower layers is 3.5cm |

KEY FEATURES OF SEMI INDUSTRIAL DEHYDRATOR

-

Premium Food-Grade Trays

Made from high-quality 304 stainless steel, these food-grade trays resist corrosion, ensure durability, and remain easy to clean. Additionally, they are dishwasher safe, making maintenance effortless for commercial use. -

Smart Time and Temperature Memory

The intelligent control system remembers previous time and temperature settings, allowing faster and easier operation for repeated recipes. Consequently, it saves time and ensures consistency in food dehydration.

-

Efficient Airflow Circulation

A rear-mounted drying fan and advanced airflow technology promote even drying, eliminating moisture buildup. Moreover, the transparent glass door allows real-time monitoring of the dehydration process. -

Energy-Saving and Automatic Control

The automatic temperature control system provides consistent heat while reducing energy consumption. As a result, it cuts heating time by 50% compared to natural sunlight, improving efficiency.

Strong and Durable Build

Constructed from high-grade stainless steel with a tempered glass door, this dehydrator offers a robust, heat-resistant design. Furthermore, the magnetic door prevents heat leakage, ensuring stable internal temperatures.

- Customizable Sizes and Easy Installation

Available in 6 to 32-tray capacities, this dehydrator adapts to different business needs. Additionally, it operates on a standard 220V power supply, making installation simple and convenient.

APPLICATIONS

-

Food Processing Businesses

Small and mid-scale food manufacturers use this dehydrator to preserve fruits, vegetables, meats, and herbs efficiently. Consequently, they extend shelf life while maintaining food quality. -

Organic Farms and Agricultural Produce Drying

Farms dry produce such as herbs, spices, and fruits using this dehydrator. Moreover, they speed up the drying process, reduce post-harvest waste, and increase product value. -

Commercial Kitchens and Restaurants

Restaurants and catering businesses prepare dried ingredients for seasoning, garnishing, and food preservation. As a result, they enhance food flavor and reduce dependency on artificial preservatives. -

Snack and Health Food Production

Companies producing dried fruit, jerky, or healthy snacks rely on this machine. Furthermore, they use its precise temperature control to ensure consistency in texture, taste, and quality. -

Herbal and Tea Processing

Herbal product manufacturers dry medicinal herbs, teas, and flowers with this dehydrator. Therefore, they maintain potency and aroma while ensuring long-term storage stability.

HOW TO USE

- Plug the plug into the house power, turn on the switch on the back of the machine

- Place the product, arrange them together so that there is space and rows.

- Put the tray into the oven. Lay flat on the floor And close the glass door

- Press the power button on the – to start using.

- Press the Timer button to adjust the time. To use in baking by pressing the + or – button to increase and reduce the time

- Set the temperature by pressing the Temp button to enter the command and press the + or – button to increase and decrease the temperature to match the raw materials.

- Wait until the baking time expired. The device will sound an alarm when the timer expired.

- Open the cabinet to remove the product. Should be careful about the heat from the grill, should wear gloves or have heat protection equipment

- Take it out to rest to release heat from the product.

- Switch off the power button.

| Size | DH06, DH10, DH16, DH32 |

|---|

1-year manufacturing warranty.

Warranty is not applicable for the following scenarios:

- The product has abnormal shapes such as broken, chipped, bent, or missing parts

- The product has been modified, changed, or repaired by someone, other than an Automicom technician

- Improper storage such as water stains, rush marks and burn marks.

- Incorrect use overuse,

- Damaged products due to external factors such as power failure, overload, etc.

- Damaged products cause by neglect of use, and not cleaning after use.

1. How many kg can one tray carry?

Each tray can carry up to 2kg of ingredients

2. What temperature should I set and how long does it take?

The setting depends on different products’ moisture content.

For example, dehydrating a whole banana takes about 10-12 hours at 70’C. Roasting pork takes about 3-4 hours at 70’C. Fresh mango takes about 10-12 hours at 40’C.

3. Can the dehydrator make crisp or bake the product until it is cooked?

The maximum temperature for this model is 90’C. Cripsy baking can be done if the product has been processed before such as by frying. It can bake until the product is cooked.

4. How long can the dehydrator work continuously?

If the temperature does not exceed 100’C, the machine can work for up to 10 hours and rest for 1 hour.

Reviews

There are no reviews yet.