Vertical Band Sealer With Inkjet Printer (BS1120VS)

$7,900.00

- Fast & Airtight Sealing – Ensures secure, leak-proof packaging for various bag materials.

- Integrated Inkjet Printer – Prints clear, smudge-free dates, batch numbers, and barcodes.

- Adjustable Conveyor & Machine Head – Accommodates bag lengths from 200mm to 700mm for versatile use.

- Durable Stainless Steel Build – Corrosion-resistant, long-lasting, and easy to maintain.

- Versatile & Mobile Design – Features a 4-wheel base with an anti-slip lock for easy movement and stable operation.

INTRODUCTION OF VERTICAL BAND SEALER WITH INKJET

Introducing Automicom Vertical Band Sealer with Inkjet delivers fast, efficient, and reliable packaging for various plastic and laminated bags. Specifically, industries like food processing, pharmaceuticals, agriculture, and chemicals rely on this machine for airtight and tamper-proof packaging. Moreover, its vertical sealing capability makes it perfect for packaging powders, granules, and liquids that require an upright position.

In addition, with an integrated Continuous Band Sealer with Inkjet, this machine not only seals bags securely but also prints essential details like manufacturing dates, batch numbers, and expiration dates. Consequently, the continuous sealing mechanism boosts production efficiency by maintaining a consistent, high-speed operation.

Furthermore, the Vertical Band Sealer with Inkjet includes adjustable temperature and conveyor speed controls, allowing businesses to customize settings for different packaging materials. Likewise, its user-friendly interface simplifies operation, while the durable stainless steel construction enhances longevity and resistance to wear. As a result, by using a Continuous Band Sealer with Inkjet, businesses can streamline packaging, improve product presentation, and ensure compliance with industry regulations. Ultimately, this machine provides a cost-effective way to optimize packaging while enhancing branding and efficiency.

SPECIFICATIONS

| Categories | BS1100VS

Ink-jet Printing Sealer |

| Voltage(V/Hz) | AC 220/50 110/60 |

| Sealing power (W) | 120 |

| Heating power (W) | 400×2 |

| Conveyor power (W) | 200 |

| Temperature control range(℃) | 0-300 |

| Speed(m/min) | 0-10 |

| Seal Width(mm) | 10 |

| Bag width (mm) | 80-400 |

| Bag Height (mm) | 200-700 |

| Conveyor size(mm) | 1780×250(LxW) |

| Air Supply pipe (mm) | Φ12 |

| Air flushing supply pipe (mm) | Φ8 |

| Distance from sealing center to product(mm) | 60 |

| Distance from sealing center to bag mouth(mm) | 50 |

| Overall conveyor load(kg) | 15 |

| External dimension(LxWxH)(mm) | 1780×650×1565 |

| Inkjet printer parameters | |

| Operating System | Linux |

| Size of Touch Screen(inch) | 5 inch |

| Touch Screen Resolution | 800×480 |

| Processor | Quad-core high-performance processor, main frequency up to 1.5GHz (fast response, smooth operation) |

| Memory | 1G+4G |

| Printing nozzle | TIJ2.5

Hot foam nozzle |

| printing letter height | 1.5-12.7mm |

| Printing length | unlimited |

| Max. Printing line | 6 lines |

| Ink type and volume | oily/42ml |

| Ink Color | Black(standard)

Optional: Red、Green、Blue、Yellow、White、Transparent |

| Printing material | suitable for any compound film material (special material needs customized ink) |

| Languages in Touch Screen | Chinese, English, Arabic, Turkish, Spanish, Portuguese, Korean, Russian (support customization) |

| Printing Content | Chinese, English, numbers, symbols, graphics, QR codes, barcodes, variable dates, variable counts, variable QR codes

Chinese, English, Numbers, symbols, graphics (support arbitrary pictures without conversion format), QR code, bar code (custom content, real-time variable barcode), variable date (custom), a variable count (custom), variable QR code (real-time variable data printing system, online system are both customized) |

| Counting | 0-100000 |

| printing volume of ink cartridge | about 200,000 times (take the production date of height 4mm and length 30mm as an example) |

| Printing content storage | can store 200 pieces (each piece of printing content has a separate counting storage function) |

| Printing font | adjustable (font can be customized ) |

| External Terminal | USB、RS232 serial Terminal、WIFI |

| Online operation | Optional (one host can control 1+N units) |

| Adjustable startup interface | Optional |

KEY FEATURES OF VERTICAL BAND SEALER WITH INKJET

-

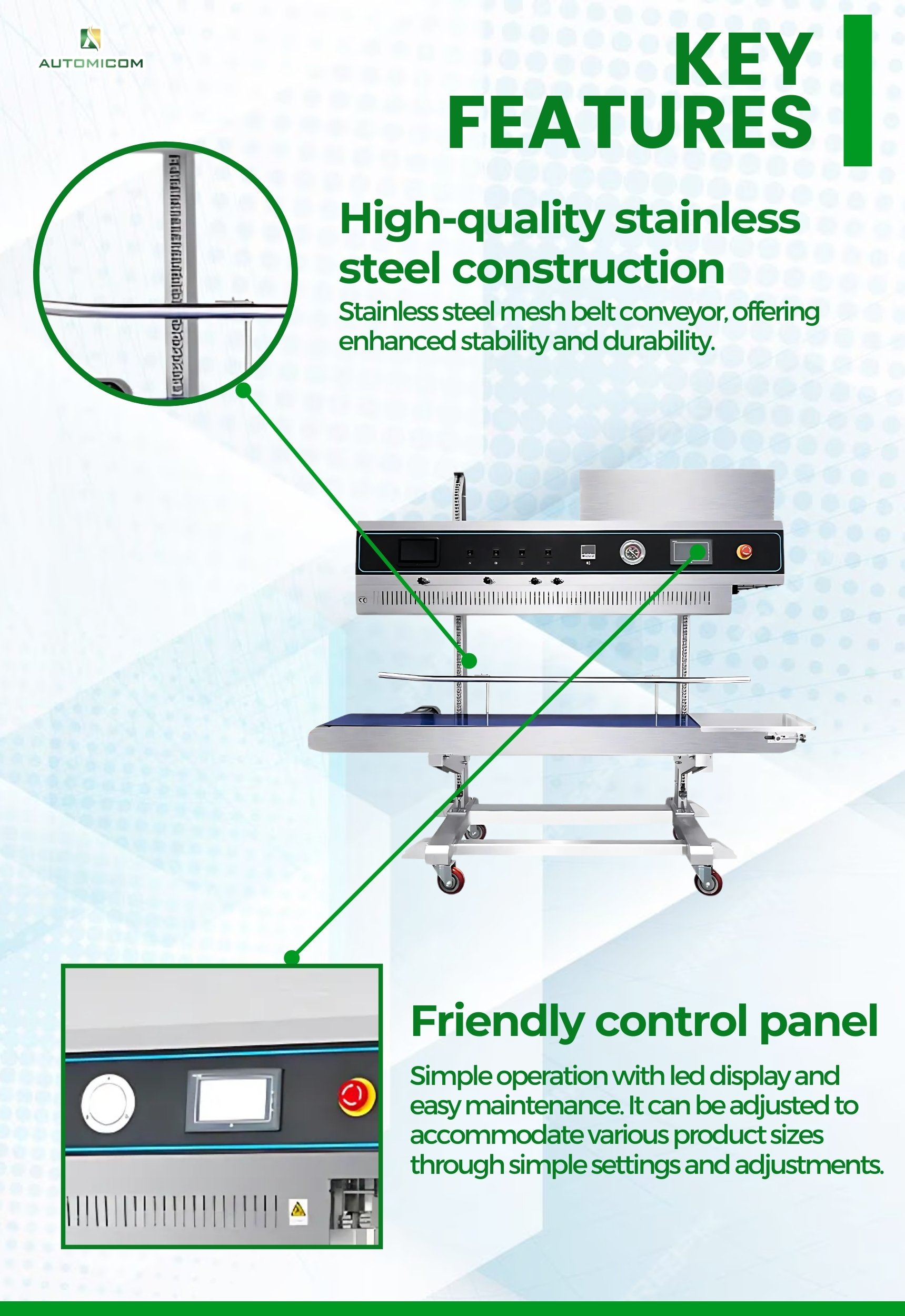

High-Quality Stainless Steel Construction – To begin with, the Vertical Band Sealer with Inkjet features durable stainless steel, ensuring long-lasting performance, corrosion resistance, and easy maintenance. As a result, it remains a reliable choice for industrial packaging.

-

User-Friendly Control Panel – Moreover, the Continuous Band Sealer with Inkjet includes an intuitive control panel that allows operators to adjust settings effortlessly. Consequently, this feature enhances efficiency while reducing training time and errors.

-

Adjustable Height of Conveyor Table & Machine Head – In addition, the adjustable design accommodates bag lengths from 200mm to 700mm, making it suitable for various packaging applications. Furthermore, the removable conveyor table provides added flexibility for handling different bag sizes with ease.

-

Versatile Use Design – Similarly, the Vertical Band Sealer with Inkjet features a 4-wheel base with an anti-slip lock, allowing smooth mobility and stable operation. Therefore, users can conveniently move the machine and operate it on a table or flat surface without instability.

-

Inkjet Coding with Clear Handwriting – Additionally, the integrated Continuous Band Sealer with Inkjet printing system ensures easy operation with precise marking. As a result, it produces clear, smudge-free batch numbers, expiration dates, and other essential details.

-

Integrated Air Suction and Gas Flushing Mode – Finally, this advanced feature enhances packaging by removing excess air or injecting gas to preserve product quality. Consequently, businesses in the food and pharmaceutical industries can extend shelf life and maintain freshness effortlessly.

CLOSER LOOK

APPLICATIONS OF VERTICAL BAND SEALER WITH INKJET

-

Food Packaging Industry

To begin with, the Vertical Band Sealer with Inkjet efficiently seals snack bags, coffee pouches, dried fruits, spices, and frozen foods. Additionally, it prints clear expiration dates and batch numbers, ensuring compliance with food safety regulations and improving product traceability. -

Pharmaceutical & Medical Industry

Moreover, this machine tightly seals medicine bags, test kits, and medical supplies to keep them safe from germs. It also prints important details like manufacturing dates and expiration dates, helping businesses follow packaging rules. -

Agricultural & Seed Industry

In addition, farmers and agricultural suppliers use the machine to package seeds, fertilizers, and animal feed securely. Consequently, this ensures long-term storage, protects against moisture, and provides clear product information for distributors and consumers. -

Chemical & Industrial Product Packaging

Furthermore, manufacturers rely on this machine to seal and code bags containing powders, granules, and liquid chemicals. As a result, it enhances safety, prevents leaks, and meets regulatory requirements for industrial product packaging. -

Retail & E-commerce Packaging

Finally, e-commerce and retail businesses use the Vertical Band Sealer with Inkjet to package cosmetics, accessories, and tools with efficiency. With professional sealing and clear date coding, it improves product presentation and builds customer trust.

FIND OUT MORE SEALING MACHINE HERE: LINK

1 year warranty

- What types of bags can this machine seal?

The continuous Band Sealer with Inkjet can seal various materials, including PE, PP, aluminum foil, laminated, and multi-layer plastic bags, making it highly versatile.

- How do I adjust the conveyor height for different bag sizes?

The Vertical Band Sealer with Inkjet features an adjustable conveyor table and machine head, accommodating bag lengths from 200mm to 700mm to fit various packaging needs.

- How long can a cartridge last?

About 200,000 times (take the production date with a height of 4mm and a length of 30mm as an example

- Are the printed words easy to wipe?

The inkjet characters do not mean that them cant be wiped off. Only after the bag is cooked and the ink seeps into the bag can it not be wiped off, At present, the ink is attached to the surface of the bag, and it can be wiped off with strong force, and the adhesion of the ink in the bag of different materials is also different.

- Is the ink cartridge too expensive?

Assuming that the price of the ink cartridge is 65USD, it can be printed 100,000 times, and the average additional cost for a bag is 0.00065USD

Reviews

There are no reviews yet.