No products in the cart.

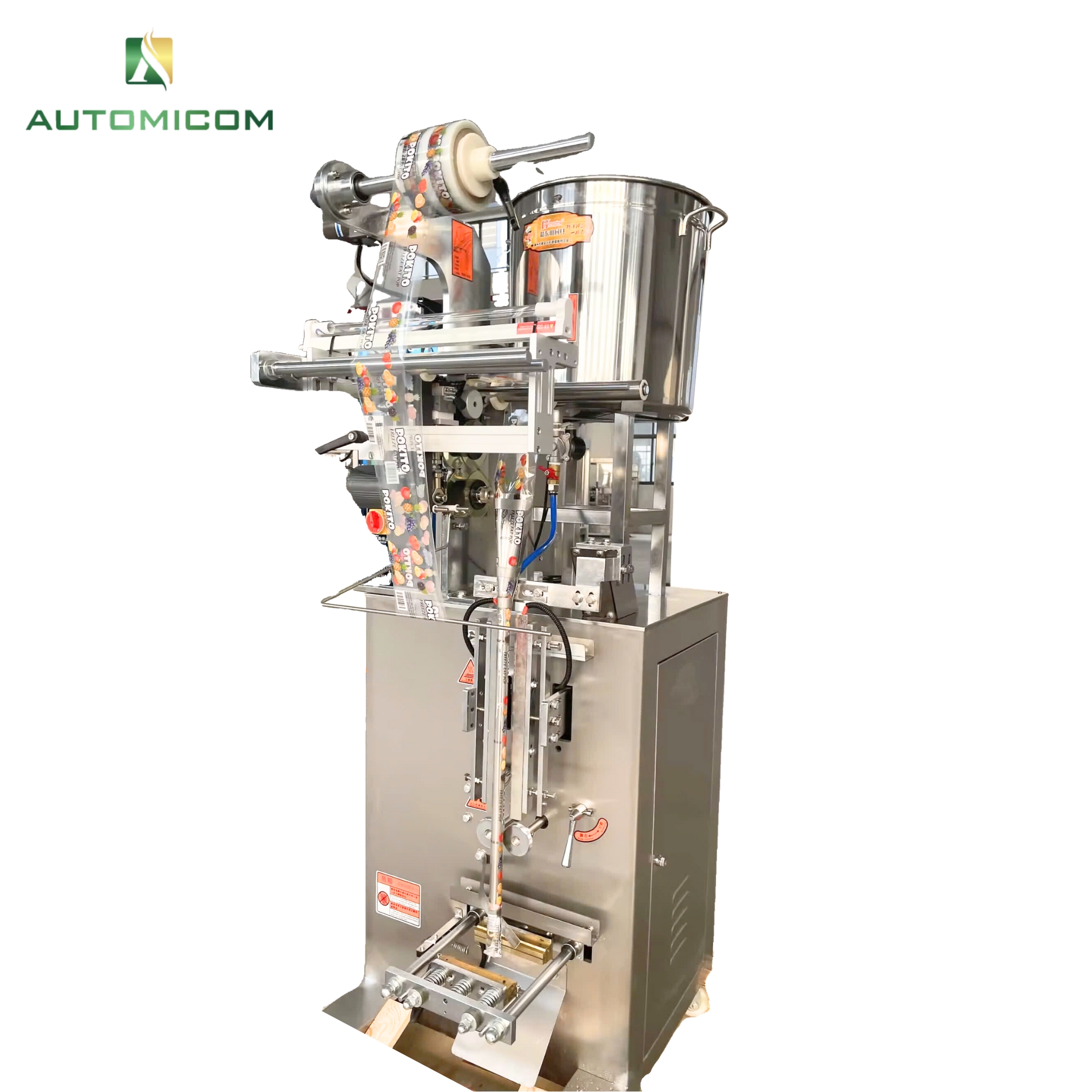

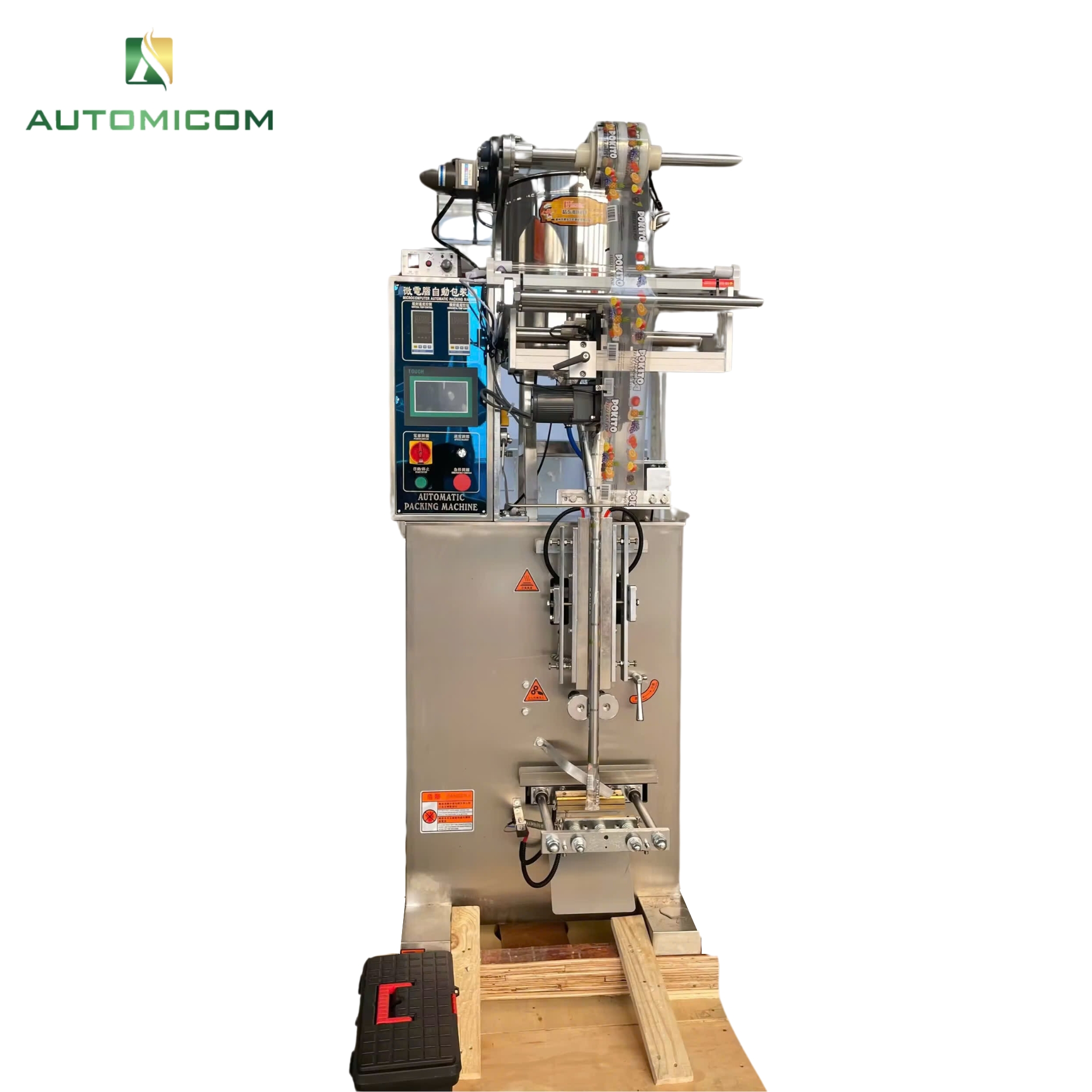

Vertical Packaging Machine (VF330Y)

Contact for price

- Made of durable, rust-proof SS304 stainless steel for long-lasting use.

- Spacious hopper minimizes refilling and boosts efficiency.

- Ensures precise filling and sealing, reducing waste.

- Safety sensors and emergency stops protect operators.

- Intuitive control panel allows easy, precise operation.

INTRODUCTION OF VERTICAL PACKING MACHINE

A Vertical Packing Machine is an indispensable tool in modern packaging operations, designed to package a wide variety of products in vertical formats efficiently. Moreover, this machine is widely recognized for its ability to streamline the packaging process, making it highly sought after in industries such as food processing, pharmaceuticals, cosmetics, and chemicals. Often referred to as an Automatic Vertical Packaging Machine, it not only enhances production speed but also ensures precision and consistency, which are essential for maintaining product quality.

A Vertical Form Fill Seal (VFFS) machine for liquid packing is an advanced packaging solution designed to efficiently package liquids into flexible pouches or bags. This automated system uses a vertical setup to form, fill, and seal packages, streamlining the entire process from raw material to finished product. Ideal for products such as beverages, sauces, oils, or dairy, the VFFS machine ensures precise and consistent filling, while minimizing waste and reducing human intervention. With its high-speed capabilities, versatility in pouch sizes, and reliability, the VFFS machine has become a preferred choice for manufacturers seeking to optimize liquid packaging operations, ensuring both speed and quality in every fill.

SPECIFICATIONS

| Model | VF330Y |

| Packing speed | 30-60 bags/min |

| Packing range | 5-300ml |

| Film width | Below 28cm |

| Bag size | L: 50-330mm, W: 15-130mm |

| Packing accuracy | ±1% (depending on products) |

| Power | 1600W |

| Power supply | 220V, 50Hz |

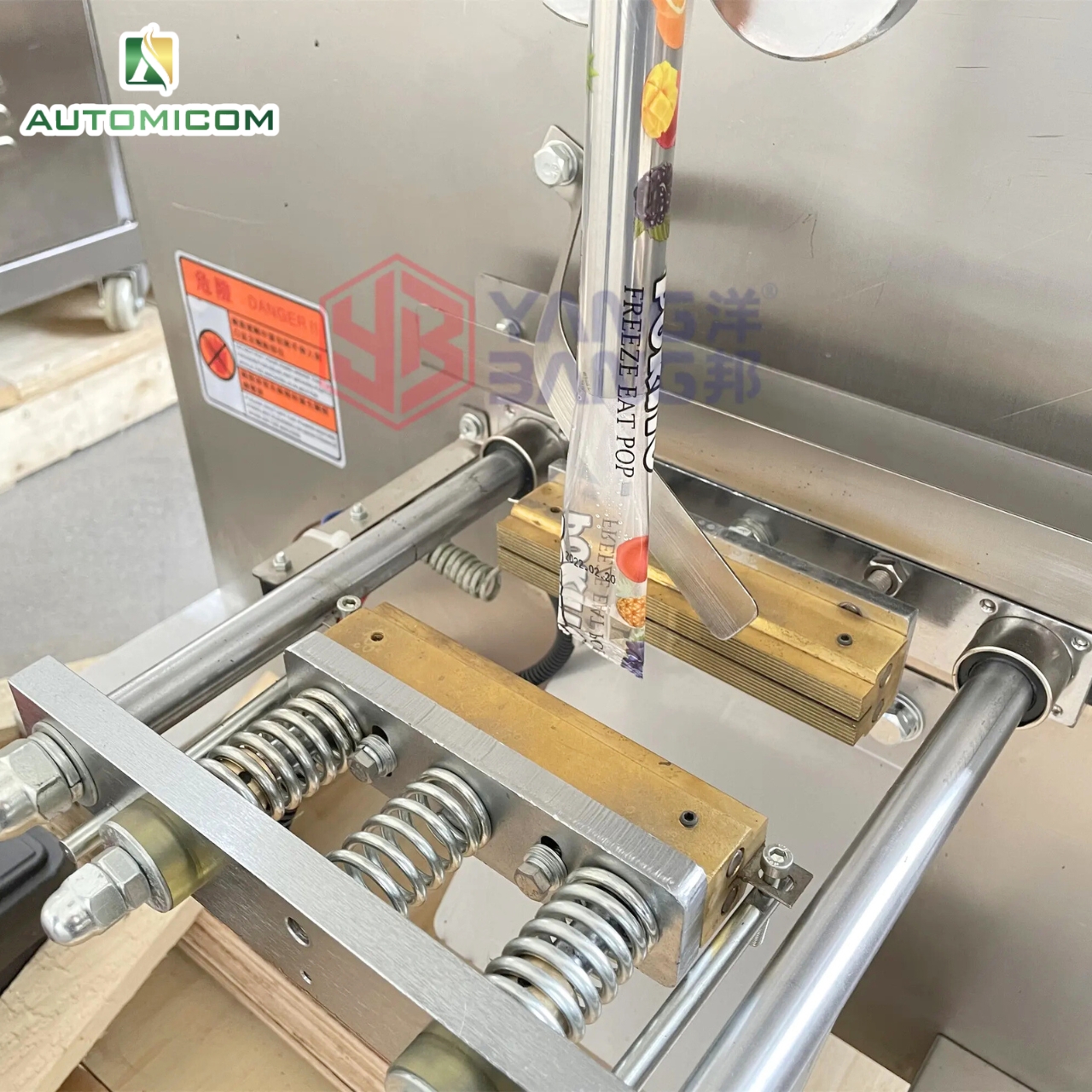

| Sealing type | 3 side sealing |

| Net weight | 260kg |

| Machine dimension | L800*W680*H1900mm |

KEY FEATURES OF VERTICAL PACKING MACHINE

Premium SS304 Material Construction

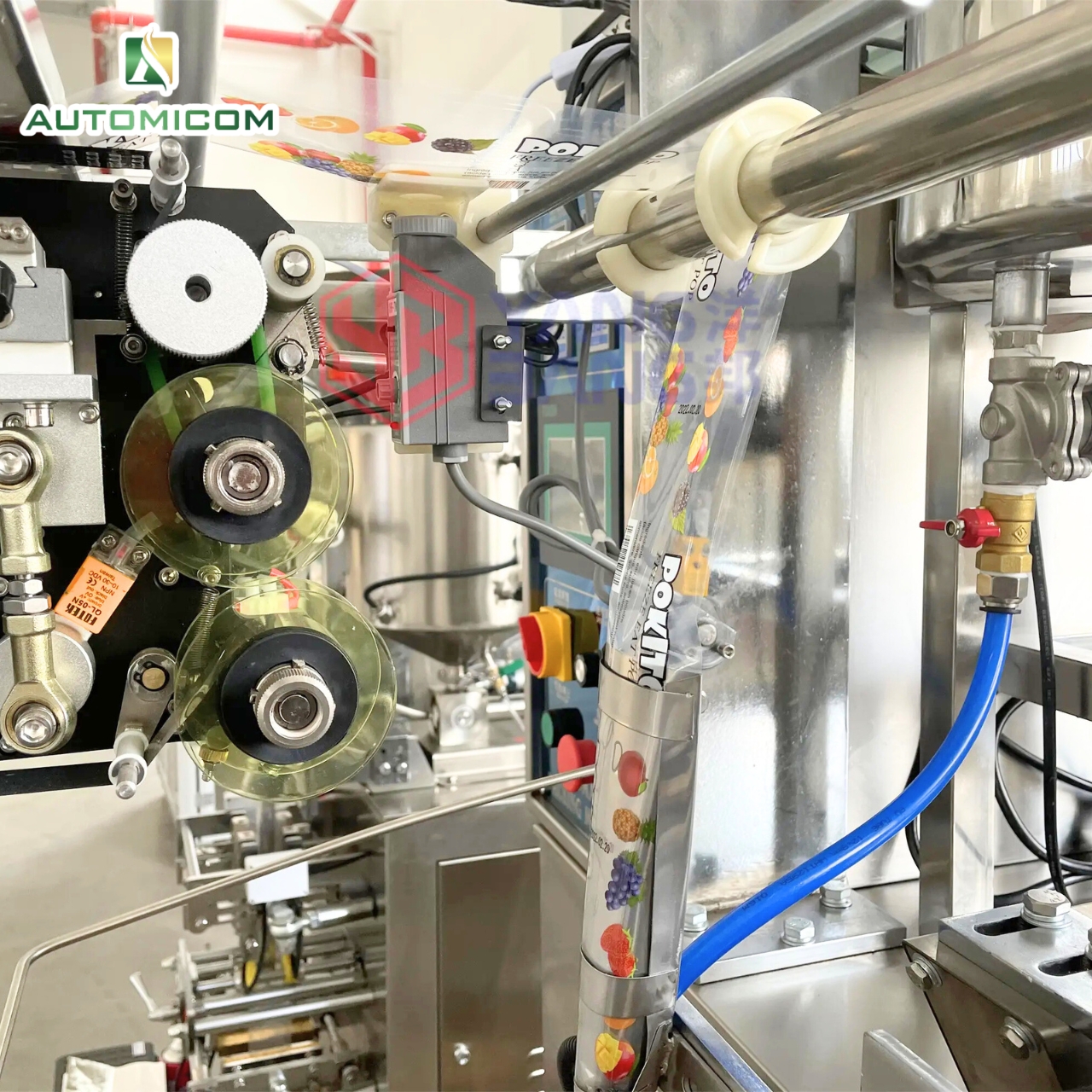

Easy Maintenance & Hygiene

Designed with ease of maintenance in mind, the machine’s parts are simple to clean and disassemble. This ensures that hygiene standards are consistently met while reducing maintenance time. Moreover, regular cleaning becomes straightforward, which minimizes downtime and keeps production on track without compromising cleanliness.

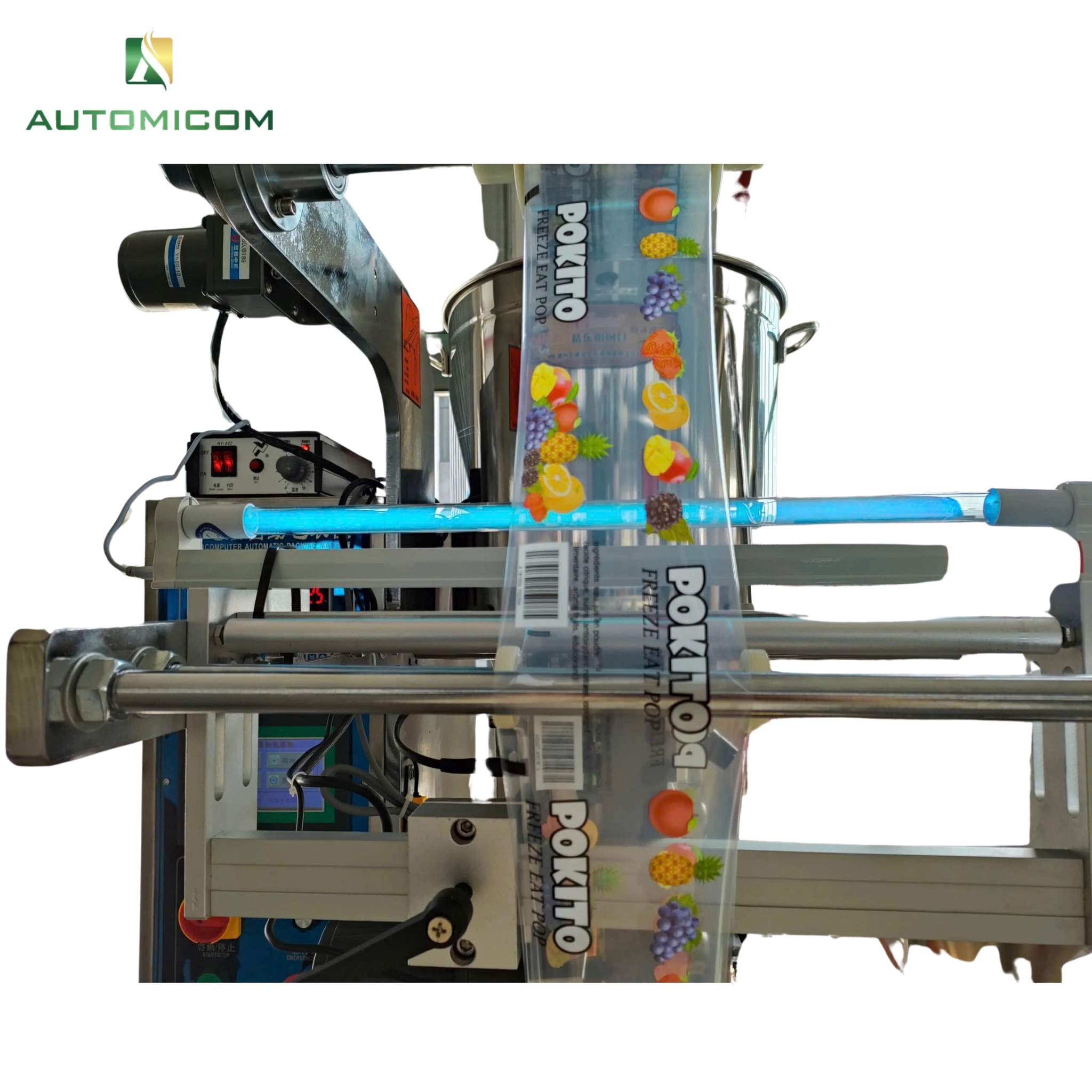

Date Printing Function

Equipped with a built-in date printing function, the machine can easily print manufacturing dates, expiry dates, or batch numbers directly onto the packaging. This feature not only ensures compliance with industry regulations but also adds an extra layer of professionalism to your product presentation, enhancing brand image and consumer trust.

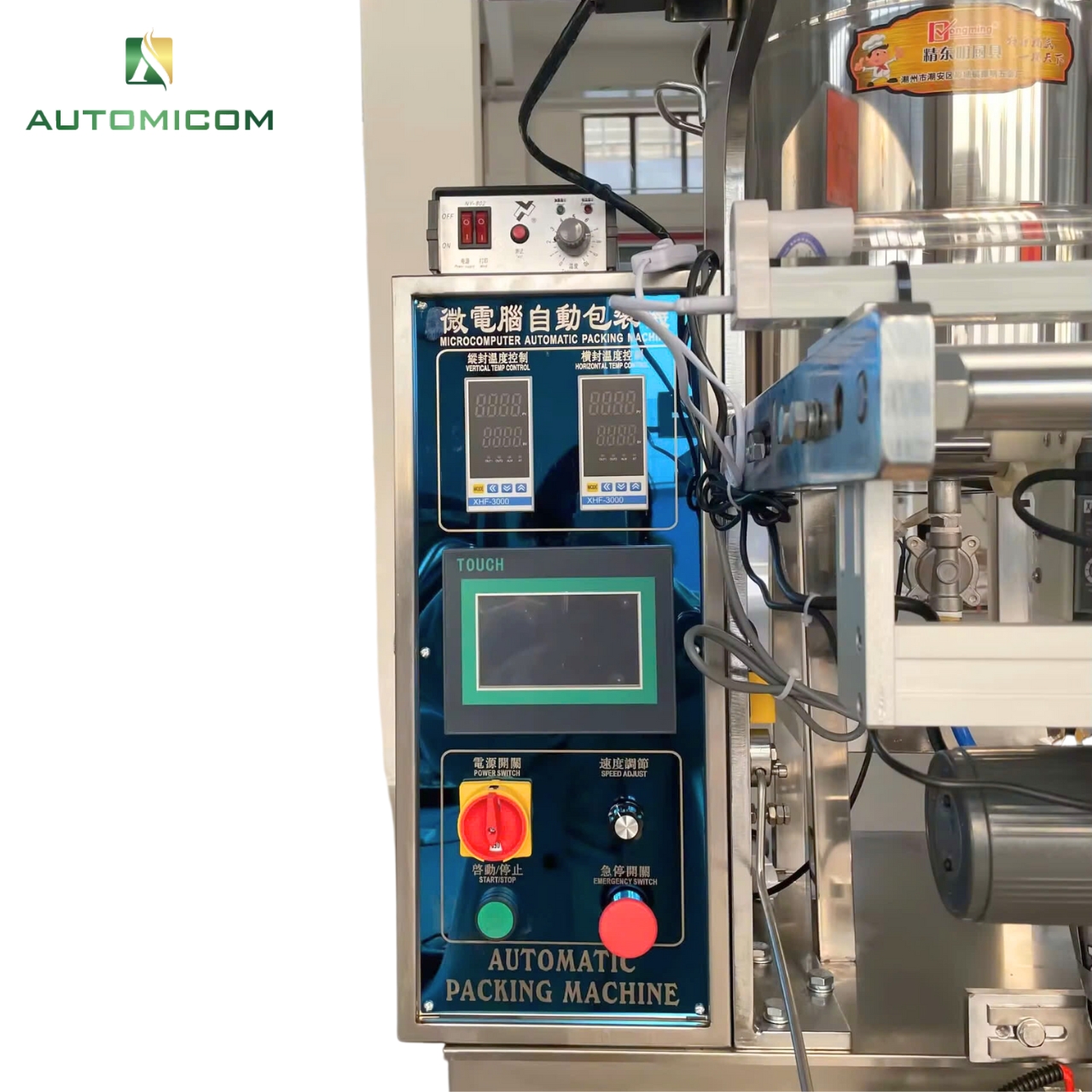

Powerful Control Panel

The digital control panel offers intuitive operation with easy-to-read displays for precise control. Operators can effortlessly adjust settings, including temperature control for heating, ensuring that liquids like yogurt or syrup are packed at the ideal consistency for optimal sealing. This level of control guarantees the highest packing standards and improves overall efficiency.

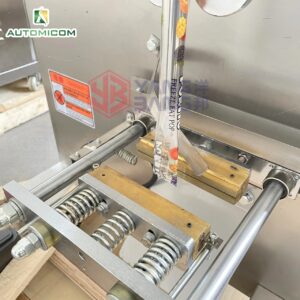

CLOSER LOOK

APPLICATIONS OF VERTICAL PACKING MACHINE

- Beverage Packaging

VF330Y machines are widely used in the beverage industry to package liquids such as juices, soft drinks, and water. These machines ensure accurate portioning and sealing of liquid products into pouches or bags, offering convenience and portability for consumers. - Dairy Products

VF330Y machines are also used to package liquid dairy products such as milk, yogurt drinks, and cream. These machines help in maintaining the product’s freshness and hygiene while providing an efficient, automated solution for high-volume production. - Sauces and Condiments

Liquid sauces, dressings, and condiments, are efficiently packaged by VF330Y machines. The ability to handle viscous liquids and control the fill volume ensures that products are packed accurately and in an appealing manner. - Liquid Pharmaceuticals

VF330Y machines are ideal for packaging liquid pharmaceuticals, such as syrups, tonics, and medical solutions. The machines maintain high levels of precision, hygiene, and safety, which are critical in the pharmaceutical industry. - Cleaning and Household Liquids

These machines are used to package cleaning liquids, detergents, and other household chemicals. The flexible packaging options help meet various packaging sizes while ensuring proper sealing to prevent leakage and contamination.

Each of these applications benefits from the speed, efficiency, and flexibility that VFFS machines provide, making them an essential part of the liquid packaging industry.

1 year warranty

- What types of products can a Vertical Packing Machine handle?

A Vertical Packing Machine is versatile and can handle a wide range of products, including powders, granules, liquids, pastes, and solid items. Common examples include snacks, spices, coffee, sugar, pharmaceuticals, cosmetics, chemicals, and pet food. The machine’s adaptability to various product consistencies and packaging styles makes it suitable for diverse industries. - Can an Automatic Vertical Packaging Machine accommodate different bag sizes and types?

Yes, an Automatic Vertical Packaging Machine is designed to be highly flexible. It can produce different bag types, such as pillow bags, gusseted bags, sachets, and sealed pouches. Additionally, the machine settings can be adjusted to accommodate various bag sizes, ensuring it meets specific packaging requirements for different products. - What are the key maintenance requirements for a Vertical Packing Machine?

Regular maintenance is crucial for ensuring optimal performance and longevity. Key tasks include cleaning the machine to prevent product buildup, checking and replacing worn-out parts like sealing jaws and belts, lubricating moving components, and calibrating sensors for accuracy. Many machines also include diagnostic systems to alert operators to potential issues, simplifying maintenance routines.

Reviews

There are no reviews yet.