2in1 Heat Shrink Machine (HS500/ HS600)

$4,300.00 – $5,900.00

- Durable Construction – Resists corrosion, wear, and high temperatures for long-lasting performance.

- Versatile Applications – Ideal for food, packaging, pharmaceuticals, electronics, and automotive industries.

- Efficient Performance – Ensures smooth, continuous operation to boost productivity.

- Hygienic Design – Easy to clean, perfect for industries with strict cleanliness requirements.

- Heavy Load Capacity – Handles bulky and heavy products with ease.

- Customizable Configurations – Adjustable belt speed, length, and width for flexibility.

INTRODUCTION OF 2IN1 HEAT SHRINK MACHINE

The 2in1 Heat Shrink Machine offers a fast and efficient way to seal and shrink-wrap products in one seamless process. As a result, it eliminates the need for multiple machines, saving both time and resources. Ideal for industries such as food, pharmaceuticals, cosmetics, and electronics, this machine boosts productivity while delivering a professional and polished finish. Moreover, its compact design is space-saving, making it an excellent choice for businesses with limited room. Additionally, the user-friendly controls make operation simple and hassle-free, allowing operators of all skill levels to achieve consistent results.

With the 2in1 Shrink Packing Machine, businesses can wrap products tightly and securely using heat, ensuring protection from dust, moisture, and tampering. In addition, the transparent shrink chamber provides clear visibility, allowing operators to monitor each step of the process, which guarantees precision and quality. Furthermore, the built-in L-bar sealer streamlines the process, eliminating extra steps and significantly reducing labor time.

What’s more, this machine works with various shrink films, including PVC, POF, and PP, offering businesses flexibility in their packaging choices. Thanks to its energy-efficient heating system, it delivers consistent shrinkage while reducing power consumption. Whether for retail shelves, e-commerce shipments, or industrial packaging, the 2in1 Heat Shrink Machine helps businesses achieve durable, attractive, and secure packaging with ease.

SPECIFICATIONS

|

Model

|

HS500

|

HS600 |

|

Type

|

2 in 1 shrink packaging machine

|

2 In 1 Shrink Packaging Machine

|

|

Power supply

|

110V,220-240V/50-60Hz

|

110V,220-240V/50-60HZ

|

|

Power

|

1.0kW

|

4.0KW

|

|

Max. Packing Size

|

550*400*300m m

|

700*600*300m m

|

|

Max. Sealing Size

|

550*400m m

|

700*600m m

|

|

Work efficiency

|

500-800 pcs/h

|

500-800pcs/h

|

|

Machine size

|

1360*670*1080m m

|

1510*870*1080m m

|

|

Machine weight

|

125kg/145kg

|

145kg/165kg

|

KEY FEATURES OF 2IN1 HEAT SHRINK MACHINE

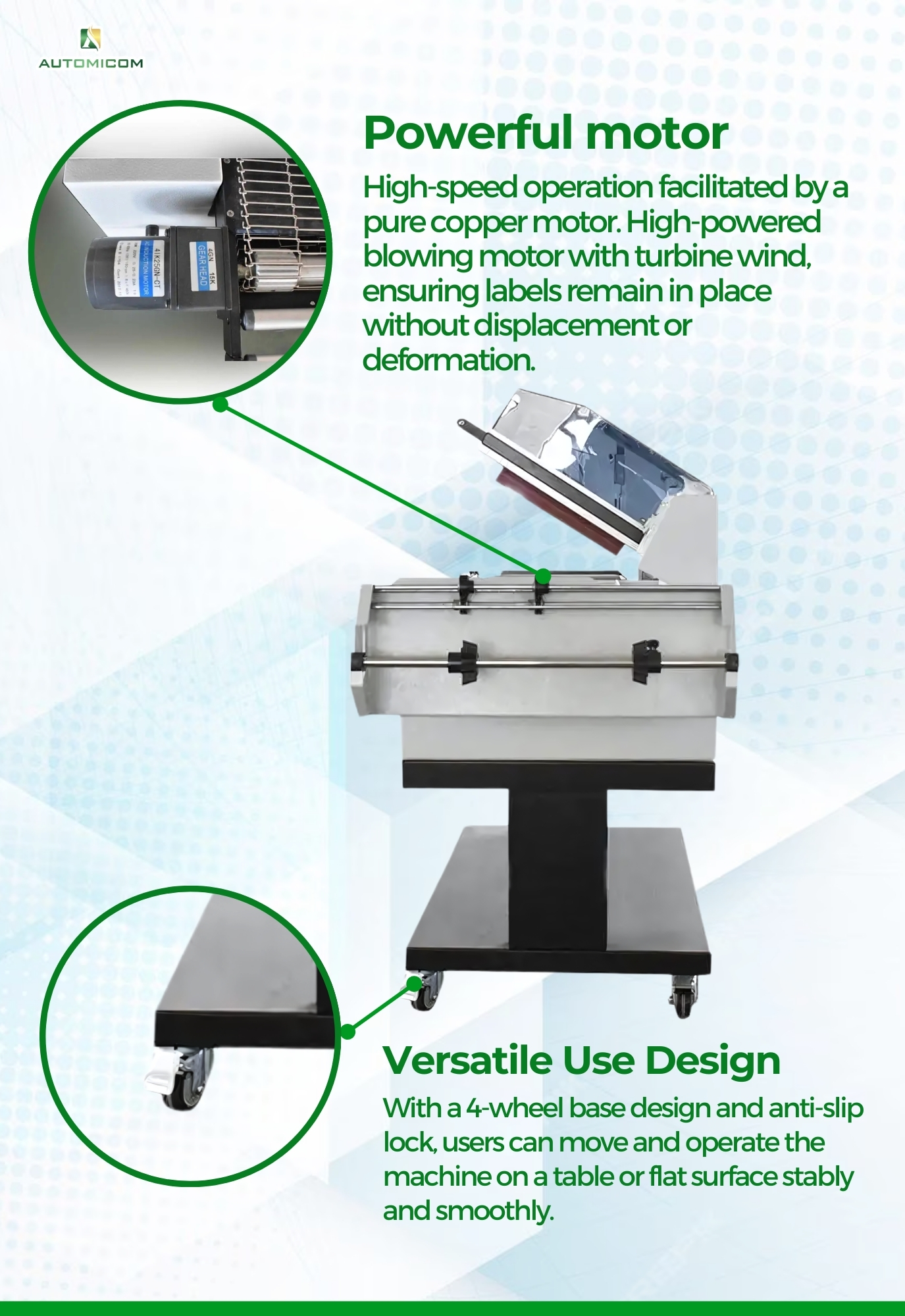

- Stainless Steel Mesh Belt Conveyor

The stainless steel mesh belt conveyor offers enhanced stability and durability, therefore ensuring reliable performance over time. Moreover, its robust construction makes it ideal for handling heavy-duty loads while maintaining consistent functionality. Additionally, the stainless steel design resists wear and corrosion, which extends the conveyor’s lifespan and reduces the need for frequent maintenance.

- Integrated Sealing & Shrinking

The machine efficiently combines sealing and shrinking into a single step, thus significantly streamlining the shrink plastic packaging process. As a result, it saves time and effort while ensuring a flawless finish.

- Versatile Use

This machine is exceptionally adaptable, making it perfect for packaging a wide variety of products. Furthermore, it guarantees a tight, professional shrink plastic finish and works with multiple types of shrink films, including PVC, POF, and PP, offering increased flexibility.

- Compact & Space-Saving Design

The compact & space-saving design of the machine ensures it saves valuable space, making it an excellent choice for businesses with limited room. Moreover, despite its smaller size, it does not compromise on performance and productivity, offering a high level of efficiency in a compact form.

- User-Friendly Operation

User-friendly operation is another key feature of the machine. Thanks to easy-to-use controls and a straightforward interface, it allows operators of all skill levels to operate it efficiently. Additionally, the transparent shrink chamber lets users monitor the process, ensuring a consistent and high-quality result at every stage.

- Adjustable Temperature & Time Settings

The adjustable temperature & time settings provide flexibility, as the machine allows users to fine-tune the shrinkage process based on the material being used. As a result, this feature guarantees optimal shrinkage for various types of shrink films, resulting in perfect packaging every time.

CLOSER LOOK

APPLICATIONS OF 2IN1 HEAT SHRINK MACHINE

- Food Processing

In food production lines, the stainless steel mesh belt conveyor plays a crucial role in handling products that require washing, drying, or cooling. Moreover, its corrosion resistance makes it especially effective in environments exposed to moisture or wet conditions, ensuring reliable and long-lasting performance.

- Packaging Industry

These conveyors are widely used in the packaging sector to efficiently transport products for sorting, labeling, and packaging. Additionally, they can handle heavy loads, which ensures smooth operation even in high-speed production lines. Moreover, they improve workflow and significantly increase efficiency.

- Pharmaceutical Manufacturing

In the pharmaceutical industry, stainless steel mesh belt conveyors move materials through various production stages. Furthermore, their hygienic design ensures they meet cleanliness standards, preventing contamination and maintaining product safety. Moreover, they are essential for adhering to strict regulatory requirements.

- Electronics Assembly

In electronics manufacturing, these conveyors move delicate components along assembly lines. Secondly, they ensure the careful handling of sensitive materials, preventing contamination and ensuring the highest quality standards.

- Metalworking & Automotive

In metalworking and automotive industries, these conveyors transport heavy parts throughout the production process. Additionally, their durability, they withstand abrasive materials and high temperatures, ensuring consistent performance and minimizing downtime.

| 2in1 Heat shrink machine | HS500, HS600 |

|---|

1 year Warranty

- What types of products can the 2in1 Heat Shrink Machine handle?

– The 2in1 Heat Shrink Machine is versatile and can handle a wide range of products, including boxes, bottles, and other items that require secure shrink plastic packaging.

- Is the 2in1 Heat Shrink Machine easy to operate for beginners?

– Yes, the 2in1 Heat Shrink Machine is designed with user-friendly controls, making it easy for operators of all skill levels to achieve consistent and professional results.

- What maintenance is required for the 2in1 Heat Shrink Machine?

– The 2in1 Heat Shrink Machine requires minimal maintenance thanks to its durable construction. Regular cleaning and occasional checks of the sealing components are typically sufficient to keep it running smoothly.

Reviews

There are no reviews yet.