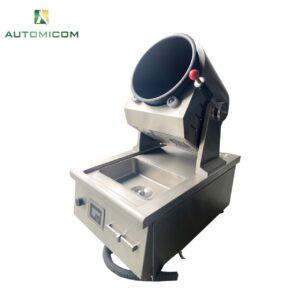

Skin vacuum packing machine (Food – SKV45)

$0.00

- Automicom skin vacuum packing machine (SKV45) has outstanding features:

- Suitable with a wide variety of materials: meat, seafood, vegetables, etc.

- The film width is up to 36cm

- Fast speed, save manpower cost

- Touch screen panel.

A skin vacuum packing machine is a specialized type of vacuum sealer that is commonly used in the food industry for packaging perishable food items such as meat, poultry, fish, and cheese. Unlike traditional vacuum sealers, a skin vacuum packing machine uses a different type of vacuum bag that conforms tightly to the shape of the product being packaged, which results in a tight, secure seal that helps to maintain the freshness and flavor of the food for longer periods of time.

Skin vacuum packing machines typically use high-quality vacuum bags that are made of a strong, durable material that is designed to withstand the rigors of the packaging process. The bags are placed over the product and then sealed tightly using a heat-sealing mechanism. The machine then uses a powerful vacuum to remove the air from the bag, which creates a tight seal that helps to preserve the food’s freshness and flavour.

Skin vacuum packing machine (SKV45) is used to seal food products over their entire surface on a thermoformed rigid tray or a pre-made skin pack tray using a special high-barrier/low-barrier flexible skin film. The skin pack film tightly encapsulates the food products and looks like a second skin on the product.

The purpose of skin vacuum packaging is to extend the shelf life of food products while minimizing the necessity for preservatives.

- Automicom skin vacuum packing machine (SKV45) has outstanding features:

- Suitable with a wide vareity of materials

- Film width is up to 36cm

- Fast speed, save manpower cost

- Touch screen panel

SKV45 is usually used with the following packing materials:

- Skin Pack Film: Skin pack films should be transparent, soft, durable, and flexible enough to package products of various shapes and sizes

- CPET Skin Pack Trays: Crystalline polyethylene terephthalate (CPET) trays are durable, heat-resistant, and microwave-safe, making them ideal for ready-to-eat VSP packaging.

- PP Skin Pack Trays: Polypropylene (PP) skin trays are more flexible than CPET trays and are usually used for packaging fresh and pre-cooked foods.

- Paperboard: Laminated paperboard is increasing in popularity with VSP applications as it allows for better merchandising and presentation. Also, it reduces the amount of plastic used in the process. It is especially popular for cheeses, fish, and other meats.

SKV skin vacuum packing machine dimension

Spacious chamber packing with 36cm max film width

Suitable for packing meat/seafood, etc.

Outstanding packing result of beef and salmon

Skin packing machines produce a beautiful appearance, and increase product value.

4 tray sizes to choose from

| Model | SKV45 |

| Electric current | 220V/50Hz |

| Power supply | 2500W |

| Air pump power | 20 bar |

| Body material | Aluminum and food-grade SS |

| Film width | 36cm |

| Machine size | 71*53*63cm |

| Chamber size | 40*31*6cm |

1-year manufacturing warranty

The warranty does not cover heating elements.

Reviews

There are no reviews yet.