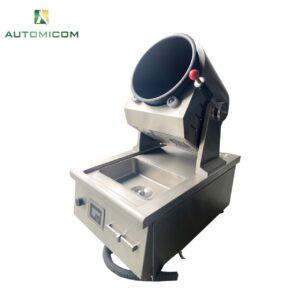

Band sealer – horizontal model

$890.00 – $1,290.00

- Full body SS304, strong and sturdy, rusty resistance

- High-quality wire, cable, motor, long-lasting

- Adjustable height to fit your bag

- Option for date printing (MGF, EXP) by date pump or black ink. Easy to change the date daily

- Complimentary accessory kit (booklet, free 2 sealing tape, 2 rubber bands)

- 1-year product warranty

A horizontal band sealer is a packaging machine that is used to seal bags or pouches horizontally. It uses a heated sealing band or wire to melt the edges of the bag together, creating a tight seal. This type of sealer is commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics.

The machine operates by feeding the bags or pouches through a conveyor belt, which then moves them past the product. The band heats up to a high temperature and applies pressure to the bags, melting the plastic and creating a secure seal. The conveyor belt then moves the sealed bags or pouches out of the machine and onto a collection table.

KEY FEATURES

Automicom horizontal band sealer is ideal for medium to high-volume packaging and sealing thermoplastic materials like polyethene, plastic-lined foil, and gusseted bags of almost any size or length.

- The conveyor belt is speed adjustable and can extend to accommodate different sizes of packaging

- Band sealer working speed is 5 times faster than impulse sealer.

- Sealing width is up to 10mm, tight and secure for packaging

- Temperature control is up to 300’C, able to seal up to 0.8mm bag thickness.

- The printing function is available for manufacturing date, expiry date, etc.

- Stainless steel structure, long-lasting and anti-corrosion

- Temperature control and speed control screen

- There are 2 models of horizontal band sealer BS310 (embosser date coding or hot stamp date coding) and BS310I (ink wheel printing).

- Band sealer comes with 5 spare sealing lines.

Product video by Automicom

This product allows for easier loading and unloading of bags, as the bags can be laid flat on the conveyor belt. Additionally, horizontal sealers are able to seal a wider range of bag materials, including thicker materials that vertical sealers may not be able to handle.

Horizontal band sealer is a reliable and efficient packaging machine that can improve the speed and quality of your packaging process. With its ability to handle a wide range of bag materials and sizes, it is an essential tool for many businesses looking to streamline their packaging operations.

SPECIFICATIONS

| Horizontal band sealer | BS310, BS310I |

|---|

1. What types of bags are suitable for this machine?

Any type of bag with PE layer will allow it to be sealed using a heat-sealing machine

2. What are the most wearable of the machine?

The most wearable part is the sealing tape and rubber band due to the long sealing time or high temperature. We give extra 2 sets for replacement. You can order spare parts from Automicom when needed</span>

It’s included changing sealing tape/rubber if needed and checking wire/cable/motor quality to prevent machine breakdown while using.</p>

4. Can I try the machine with my bags before purchasing it?

Yes. You can arrange an appointment to visit our showroom to try the machine.

Reviews

There are no reviews yet.