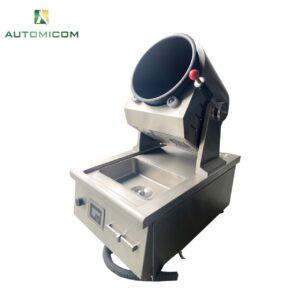

Heat shrink machine HS200/HS300/HS400

$1,900.00 – $2,800.00

Uniform Shrinkage:

Heat shrink machines ensure uniform and consistent shrinkage across the entire surface of the packaged

item. This results in a professionally wrapped appearance, enhancing the overall presentation of the product.

Versatility:

These machines are adaptable to a wide range of product shapes and sizes. Whether packaging individual items or bundling multiple products together, heat shrink machines provide flexibility and versatility in

meeting diverse packaging needs.

Time Efficiency:

Heat shrink machines are designed for efficiency, offering quick and reliable shrinkage in a matter of seconds. This time-saving feature contributes to increased productivity in packaging operations.

Sealing and Protection:

The heat sealing process not only creates a secure barrier around the product but also provides protection against external elements, such as dust and moisture. This is particularly beneficial for preserving the quality and integrity of the packaged items.

A heat shrink machine HS300 is a versatile and efficient tool used for packaging and sealing various products with shrinkable films. It employs the principle of heat to shrink the film tightly around the item, creating a secure and visually appealing package. Here are some key features of heat shrink machines:

Uniform Shrinkage:

Heat shrink machines ensure uniform and consistent shrinkage across the entire surface of the packaged

item. This results in a professionally wrapped appearance, enhancing the overall presentation of the product.

Versatility:

These machines are adaptable to a wide range of product shapes and sizes. Whether packaging individual items or bundling multiple products together, heat shrink machines provide flexibility and versatility in

meeting diverse packaging needs.

Time Efficiency:

Heat shrink machines are designed for efficiency, offering quick and reliable shrinkage in a matter of seconds. This time-saving feature contributes to increased productivity in packaging operations.

Sealing and Protection:

The heat sealing process not only creates a secure barrier around the product but also protects against external elements, such as dust and moisture. This is particularly beneficial for preserving the quality and integrity of the packaged items.

Intelligent digital display temperature controller, adjustable temperature, clear and precise digital display. When the temperature of the shrinking tunnel reaches the set temperature, the machine automatically stops heating, ensuring the temperature of the shrinking furnace is stable and energy-saving.

The new generation of HS machines uses Infrared heaters. These heaters emit electromagnetic radiation in the infrared range. They generate heat when the radiation is absorbed by the targeted object, in this case, the packaging material or shrink film. Infrared heaters are known for their direct and efficient heat transfer.

Robust machine construction and design, a significant improvement over its predecessor. It is conveniently outfitted with wheels for easy mobility and is designed to optimize space utilization.

| SIZE | HS200, HS300, HS400 |

|---|

**Warranty Information:

Main parts are covered by a 12 months warranty. This warranty does not apply to durable parts such as heating elements, belts, rollers and fuses.

**Warranty Exclusions

The warranty does not cover machine damage resulting from neglect, mishandling, falls, or any other causes other than manufacturing defects. Automicom reserves the right to reject warranty claims or charge a repair fee if the damage is determined not to be due to a manufacturing defect.

**Warranty Condition

Customers are responsible for arranging the logistics to send the machine to our service centre for repair and to pick it up afterwards.

1. What types of materials can be processed with a heat shrink tunnel?

Answer: A heat shrink tunnel is designed to work with various types of shrink films, such as polyolefin (POF), polyethene (PE), and polypropylene (PP). It is commonly used for packaging products in shrink film for industries like food and beverage, pharmaceuticals, and consumer goods. Always check the manufacturer’s specifications to ensure compatibility with the film and materials you intend to use.

2. What maintenance is required for a heat shrink tunnel?

Answer: Regular maintenance is crucial for ensuring the efficient operation of a heat shrink tunnel. Key maintenance tasks include:

- Cleaning: Regularly clean the tunnel, conveyor belts, and any surfaces that come into contact with shrink film or product residue. Avoid using abrasive cleaners that could damage the machine.

- Inspecting Heating Elements: Check heating elements for signs of wear or damage and replace them if necessary. Proper functioning of the heating elements is essential for consistent shrinkage.

- Lubrication: Apply lubrication to moving parts such as conveyor rollers and bearings according to the manufacturer’s recommendations to prevent wear and ensure smooth operation.

- Checking for Wear: Regularly inspect belts, seals, and other components for signs of wear or damage and replace them as needed.

Reviews

There are no reviews yet.