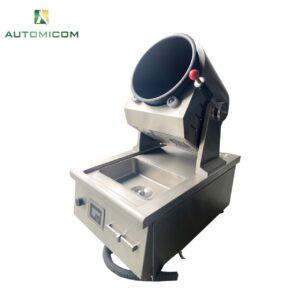

Vertical Band Sealer with Nitrogen flushing ( BS500S/ BS500P)

$2,800.00

- Full body SS304, strong and sturdy, rusty resistance

- High-quality wire, cable, motor, long-lasting

- Adjustable height to fit your bag

- Option for date printing (MGF, EXP) by date pump or black ink. Easy to change the date daily

- Complimentary accessory kit (booklet, free 2 sealing tape, 2 rubber bands)

- 1-year product warranty

- Nitrogen Gas Flushing

A Vertical Band Sealer with Nitrogen flushing is a packaging machine that is used to seal bags or pouches horizontally. It uses a heated sealing band or wire to melt the edges of the bag together, creating a tight seal. This type of sealer is commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics.

The machine operates by feeding the bags or pouches through a conveyor belt, which then moves them past the sealing band. The band heats up to a high temperature and applies pressure to the bags, melting the plastic and creating a secure seal. The conveyor belt then moves the sealed bags or pouches out of the machine and onto a collection table.

KEY FEATURES

Automicom Vertical Band Sealer with Nitrogen flushing is ideal for medium to high-volume packaging and sealing thermoplastic materials like polyethylene, plastic-lined foil, and gusseted bags of almost any size or length.

- The conveyor belt is speed adjustable and can extend to accommodate different sizes of packaging

- Band sealer working speed is 5 times faster than impulse sealer.

- Sealing width is up to 10mm, tight and secure for packaging

- Temperature control is up to 300’C, able to seal up to 0.8mm bag thickness.

- The printing function is available for manufacturing date, expiry date, etc.

- Stainless steel structure, long-lasting and anti-corrosion

- Temperature control and speed control screen

- There are 2 models of horizontal band sealer BS500P (Nitrogen gas flushing, Inox material) and BS500S ((Nitrogen gas flushing, SS304 material).

- Band sealer comes with 5 spare sealing lines.

SPECIFICATIONS

|

Model |

BS500S/P |

|

Power supply |

220V, 50Hz |

|

Power consumption |

500W |

|

Sealing speed |

0-12m/min |

|

Sealing width |

6-12mm |

|

Sealing film thickness |

0.02-0.08mm |

|

Temperature range |

0-300’C |

|

Conveyor loading |

5kg |

|

Machine size |

1000*350*780mm |

|

Machine weight |

35kg |

APPLICATIONS

- Food Packaging:

The Vertical Band Sealer with nitrogen flushing is widely used in the food industry to package products like snacks, coffee, and perishable items. The nitrogen flushing process removes oxygen, extending shelf life and maintaining freshness.

- Pharmaceutical Packaging:

In the pharmaceutical sector, this sealer is employed to package sensitive products such as powders and tablets. Nitrogen flushing protects the integrity of the products by minimizing oxidation and contamination.

- Cosmetic and Personal Care Products:

This sealer is also used for packaging cosmetics and personal care items, such as creams and lotions. Nitrogen flushing prevents product degradation and maintains quality by keeping moisture and air away from the contents.

1 year

Reviews

There are no reviews yet.