No products in the cart.

Band sealer – vertical type (BS410 and BS410I)

Price range: $990.00 through $1,350.00

- Full body SS304, strong and sturdy, rusty resistance

- Option for date printing (MGF, EXP) by date pump or black ink. Easy to change the date daily

- 1-year product warranty.

The vertical band sealer is an efficient packaging machine that seals bags or pouches in an upright position, making it ideal for liquids, powders, or loose items. Additionally, it uses a heated sealing band or wire to melt the edges of the packaging material, thereby forming a reliable, tight seal. As a result, industries such as food, beverages, pharmaceuticals, cosmetics, and consumer goods rely on these sealers for their versatility in handling various bag sizes and materials.

Moreover, the machine operates simply: bags or pouches are fed through rollers, which guide them past the heated sealing band for precise sealing. As the packaging heats up, the band melts the plastic, creating a secure, airtight seal that protects the contents. Subsequently, the sealed bags or pouches are moved out of the machine onto a collection table, ready for further processing or shipment. Overall, this continuous sealing process ensures consistent, high-speed production, making vertical band sealers essential for high-volume packaging operations.

KEY FEATURES

The Automicom vertical band sealer is ideal for medium to high-volume packaging. It seals thermoplastic materials like polyethylene, plastic-lined foil, and gusseted bags. It efficiently handles bags of nearly any size or length.

- The conveyor belt is speed adjustable and can extend to accommodate different sizes of packaging

- Band sealer working speed is 5 times faster than impulse sealer.

- Sealing width is up to 10mm, tight and secure for packaging

- Temperature control is up to 300’C, able to seal up to 0.8mm bag thickness.

- The printing function is available for manufacturing date, expiry date, etc.

- Stainless steel structure, long-lasting and anti-corrosion

- Temperature control and speed control screen

- There are 2 models of BS410 (embosser date coding or hot stamp date coding) and BS410I (ink wheel printing).

- This product comes with 2 spare sealing lines.

This product is a reliable and efficient packaging machine designed to improve speed and quality in packaging. It handles a variety of smaller bags and pouches with ease. As a result, it is an essential tool for streamlining packaging operations.

APPLICATIONS

- Food Packaging: Sealing bags containing snacks, frozen foods, or perishable items to ensure freshness and prevent contamination.

- Pharmaceutical Packaging: Sealing pouches for medicines, vitamins, or supplements to maintain product integrity and comply with safety regulations.

- Cosmetics and Personal Care: Packaging lotions, creams, and other beauty products in sealed bags to protect them from air and moisture.

- Chemical Packaging: Sealing bags containing powders, granules, or liquids in industries such as agriculture, detergents, and industrial chemicals.

- Pet Food Packaging: Ensuring secure seals for bags containing dry pet food or treats, keeping them fresh and safe from pests.

| Vertical band sealer | BS410, BS410I |

|---|

Warranty term: This product comes with a 6-month warranty covering the main parts, excluding the heating element and spring mechanism.

If the machine encounters any issues, please send it to our servicing center for inspection and repair. On-site service is not available for this model.

Be the first to review “Band sealer – vertical type (BS410 and BS410I)”

KEY FEATURES OF DEHYDRATOR MACHINE (6-16 TRAYS)

Automicom food dehydrator is built with a strong SS201 stainless steel body, providing excellent structural stability and long-term durability. The brushed stainless steel finish gives the machine a clean, professional appearance while remaining easy to maintain.

Inside, the unit features food-grade SS304 stainless steel trays, ensuring safe and hygienic contact when you dehydrate food. The spacious tray design allows you to load more ingredients at once, improving efficiency and maximizing productivity for both home and small business use.

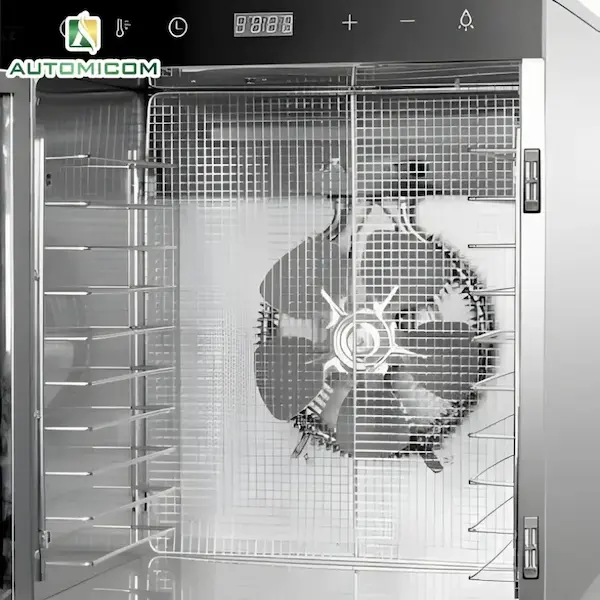

The interior of the dehydrator is designed for maximum capacity and flexibility. Multiple stainless steel trays are neatly arranged to provide ample space for evenly spreading food, allowing efficient airflow between each layer.

The dehydrator features a well-designed rear ventilation for stable and efficient operation. The large circular vent contains a powerful circulating fan that ensures consistent airflow throughout the chamber and preventing overheating and maintaining stable internal temperature during long hours of operation.

A circulating fan system is designed to ensure consistent, uniform airflow throughout the dehydrator's chamber. The rear-mounted fan distributes warm air evenly across all trays, eliminating hot spots and reducing uneven drying.

The optimized airflow system works together with precise temperature control to preserve food texture, color, and nutrients.

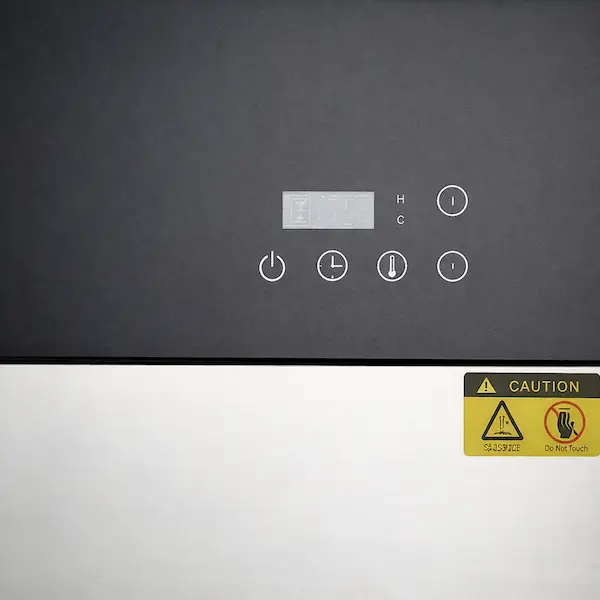

The dehydrator features a simple and intuitive control panel, designed for easy operation. With adjustable temperature control from 30°C to 90°C, you can precisely set the ideal drying condition for fruits, vegetables, herbs, meat, and more.

The built-in 24-hour timer setting allows you to customise drying time according to different food types.

Actual Results from Our Dehydrating Machine

Freshly sliced fruits are evenly dried on stainless steel mesh trays, preserving their natural colour, texture, and flavour. The moisture is carefully removed to create lightweight, long-lasting dried fruits—perfect for healthy snacks, retail packaging, or vacuum sealing for extended shelf life.

Sliced meat is evenly dehydrated to achieve a firm, dry texture while retaining its rich color and natural flavor. Ideal for jerky production or pet treats, the final product has reduced moisture, extended shelf life, and is ready for packaging or vacuum sealing

Fresh ginger, garlic, lemongrass, and chili are evenly dried to preserve their strong aroma and natural flavor. The final dehydrated herbs are lightweight, easy to store, and ideal for grinding into powder, tea blends, spice mixes, or long-term food production

Why choose Automicom Dehydrator?

Reviews

There are no reviews yet.