No products in the cart.

INTRODUCING OUR SEALING MACHINES

Automicom Sealing Machines deliver fast, secure, and reliable seals for a wide range of industries. Built for efficiency and precision, they ensure product protection and consistent packaging quality.

Impulse sealer

Foot Pedal Sealer

Band Sealer

Band sealer with with special features

Product videos by Automicom

Industrial vertical band sealer (BS600).

Vertical band sealer (BS410)

Horizontal band sealer (BS310 and BS310I).

Horizontal band sealer with vacuum and nitrogen flushing

Why choose sealing machines from Automicom?

1 year manufacturing warranty

Ready stock of spare parts

Technical support

What is a bag sealing machine?

Bag sealing machines are the packaging device designed to seal plastic or other flexible packaging materials, helping to preserve product freshness, prevent contamination, and improve shelf life. Commonly used in industries like food, pharmaceuticals, hardware, and retail, these machines are crucial in efficient and secure product packaging.

How Does a Sealing Machine Work?

The basic function of a sealing machine is to apply heat and pressure to the open edge of a bag, melting the material and bonding it together to form a tight seal. Depending on the type of product and packaging material, different sealing methods are used. For example, one of the most popular types is the heat sealer, which uses a heated element to melt the plastic and seal the bag. Additionally, there are manual, semi-automatic, and automatic models available to suit various production needs. Overall, sealing machines offer versatile solutions for packaging.

Types of Sealing Machines

- Impulse Heat Sealer: It heats only when the sealing bar is pressed down, making it energy-efficient and safe for most plastic bags.

- Foot Pedal Sealer – Allows hands-free operation, ideal for medium to high-volume sealing.

- Band Sealer – Used for continuous sealing of bags, perfect for production lines.

- Modified atmosphere band sealer – helps preserve freshness, prevent oxidation, and maintain product quality

Impulse heat sealers

An impulse heat sealer is a compact and highly efficient sealing device used to seal plastic bags and thermoplastic materials. Unlike constant heat sealers, an impulse sealer only generates heat when the sealing arm is pressed down, making it energy-efficient and safe to use, especially in low to medium-volume packaging environments

Types of Impulse Sealers

1.Hand Impulse Heat Sealer (Sealing machines series)

This is a tabletop model operated manually, ideal for sealing poly bags and light-duty packaging. It’s suitable for retail shops, small factories, or home-based businesses.

2. Handheld Sealer (Sealing machines series)

A handheld sealer is a portable version that can be used without a table. It’s perfect for sealing irregularly shaped or bulky items that can’t fit into a conventional sealing machine.

Foot Pedal Sealer

The foot pedal sealing machine operates based on the principle of using a foot pedal to apply force, allowing two sealing bars to close, melt, and tightly seal two layers of bags together. The foot pedal bag sealing machine delivers much higher productivity than manual sealing machines. For this reason, many small and medium-sized manufacturing facilities use it to package food, tea, coffee, pharmaceuticals, and more. Automicom offers the PFS series to help businesses boost efficiency and output without relying on manual effort. This machine handles various bag types with widths of up to 80 cm. Its compact design frees up space in your workspace. The foot pedal sealer features a high-quality transformer and heat sealing component that deliver durable performance and consistent, high-quality packaging results for your business.

Band Sealer

A band sealer is a high-efficiency packaging machine designed to seal bags continuously and quickly. Ideal for medium to high-volume production, the continuous band sealer operates by moving bags along a conveyor while applying consistent heat and pressure for strong, reliable seals. Whether you’re sealing food, medical supplies, or industrial products, an automatic band sealer machine offers speed and convenience. Advanced models like the vacuum band sealer and band sealer with nitrogen flush also support modified atmosphere packaging to extend shelf life and maintain product quality.

Automicom’s BS series of continuous bag sealing machines are commonly used in packaging industries such as food and beverages, pharmaceuticals, and cosmetics. The continuous band sealer from Automicom is suitable for packaging with medium to high productivity, compatible with various bag types such as polyethylene, smooth bags, embossed bags, silver bags, aluminum bags, in various sizes. The conveyor speed is adjustable and can be extended to fit different packaging sizes. The machine’s working speed is more than 5 times faster than regular bag sealing machines. The sealing width is up to 10mm, ensuring a tight and secure packaging. The temperature control goes up to 300°C, allowing the sealing of bags with a thickness of up to 0.8mm. Printing functions are available for production dates, expiration dates, etc. The machine’s body is made of stainless steel, ensuring durability and corrosion resistance.

Modified atmosphere band sealer

A modified atmosphere band sealer is a specialised packaging machine designed to extend product shelf life by replacing the air inside the package with gases like nitrogen before sealing. This process helps preserve freshness, prevent oxidation, and maintain product quality. Ideal for food, pharmaceutical, and electronic products, it combines high-speed sealing with options like vacuum and gas flush for efficient and secure packaging.

Automicom offers several band sealer models designed to meet different production capacities, speeds, and functions. Models BS310NS and BS150S feature a compact tabletop design, ideal for small to medium-scale sealing with nitrogen flushing. For higher performance needs, models BS1120 and BS500S are equipped with both vacuum and nitrogen flushing functions, making them suitable for more advanced packaging requirements.

Criteria for Choosing a Bag Sealing Machine

Choosing a bag sealing machine requires careful consideration to ensure that you are investing in a product that meets your specific needs. Here are some important criteria:

Purpose of Use:

Depending on the intended use, individuals can choose a suitable machine model. For small business households or small wholesale points, a handheld bag sealing machine may be suitable. This type of machine is electric and requires users to place it on a flat surface, adjust the appropriate sealing temperature, and use their hand to lightly press the sealing bar to seal the packaging.

For large wholesale stores with high packaging needs, a foot pedal bag sealing machine is a perfect choice. This type of machine is larger in size. Users only need to adjust the appropriate temperature and use their foot to lightly press on the machine’s pedal to operate it. The advantage of this machine is its high capacity, capable of sealing long lines up to 80cm and compressing thick bags with a weight of up to 15kg.

Additionally, for large-scale production and packaging workshops, a continuous bag sealing machine will meet these needs. This type of machine includes automatic conveyors. To continuously seal bag mouths, users only need to adjust the appropriate temperature and conveyor speed. Then, place the bags on the conveyor, and let the machine automatically run to position each bag for sealing. The notable advantage of this bag sealing machine is its ability to continuously seal bags at a rate of 1000 – 2000 bags per hour, producing strong and secure sealing lines.

Machine Design:

Bag sealing machines come in various designs and sizes. Choose a machine that fits your workspace and the type of bags you want to package. Typically, there are two types: vertical and horizontal. Vertical machines are suitable for packaging powder or liquid goods, while horizontal machines are ideal for sealing bags containing dry items without spillage.

Product Cost:

The cost is also a factor that customers are concerned about. When researching a product, the quality of the bag sealing machine significantly determines its durability, lifespan, and productivity during use. It is advisable to purchase from brands and manufacturers with high consumer ratings. Although there are many suppliers offering machines at different prices, customers should determine their budget and seek a bag sealing machine with suitable quality and cost.

Automicom ensures competitive machine prices with superior quality compared to other addresses in the market. This allows customers to save additional costs. Moreover, the company regularly offers promotions on holidays and anniversaries.

Automicom’s Best Types of Bag Sealing Machines

Handheld Bag Sealing Machine

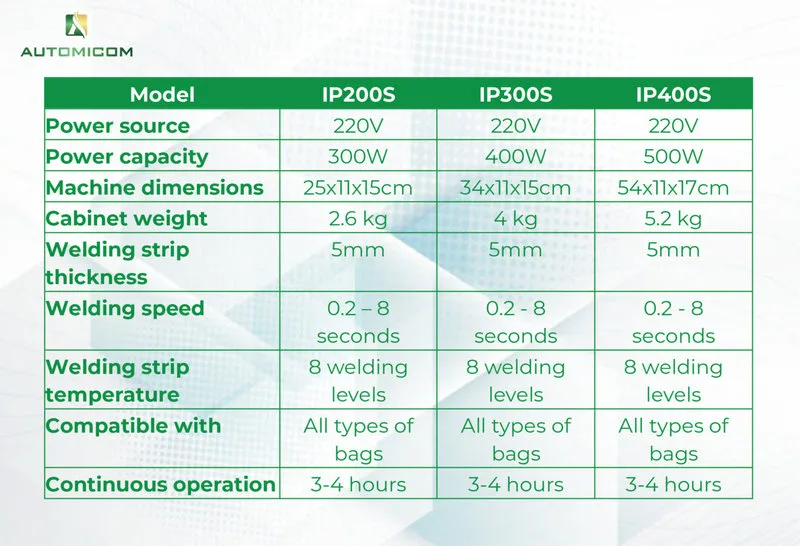

– IP200S/300S/400S Handheld Bag Sealing Machine

The IPS bag sealing machine from Automicom, also known as a heat sealer, is a packaging machine that uses heat to seal various types of bags and plastic films. The machine operates by applying pressure and heat to the material, melting the plastic, and sealing them together. Moreover, the IPS bag sealing machine is flexible, easy to use, making it a popular choice for various industries, including food, pharmaceuticals, electronics, and more.

The operator presses down on the machine’s handle to activate the heating element. The machine applies heat to the sealing bar, melting the plastic material and creating a sealed line. The sealing process is quick and efficient, typically taking only a few seconds.

The IPS bag sealing machine comes in various sizes and designs to meet different needs (20/30/40cm). The handheld machine is compact and convenient, suitable for sealing small bags or irregularly shaped items. Larger IPS machines can seal bags and films of various sizes, with some machines capable of sealing bags up to 40cm long. The sealing width can reach up to 5mm.

Moreover, the IPS bag sealing machine is suitable for sealing various types of bags, such as polyethylene bags, polypropylene bags, and other thermoplastic films. They can create a tight sealing strip, providing waterproofing to preserve items inside the bag and protect them from external factors such as moisture, dirt, and waste.

Unlike other machines on the market, typically made of plastic, Automicom’s handheld bag sealing machines are upgraded with aluminum and copper motor components, enhancing their durability and performance.

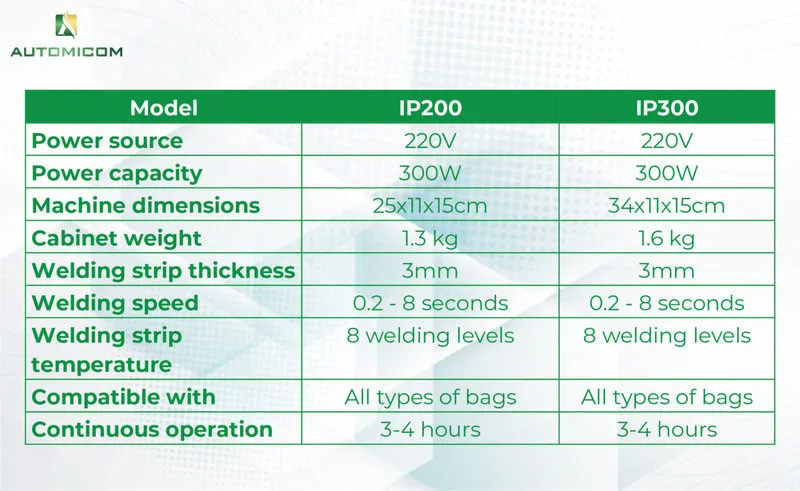

IP200/300 Handheld Bag Sealing Machine

Similar to the IPS series, the IP200/300 series is a line of handheld bag sealing machines with a compact size suitable for household use. It is ideal for sealing bags to preserve food, such as sealing candy or snack bags that haven’t been fully consumed. Additionally, it can be used to seal food bags to extend their shelf life. Using a bag sealing machine instead of clips or rubber bands enhances preservation capability and adds aesthetic appeal to the product. However, unlike the IPS series, the IP series machine body is made from high-quality ABS plastic, making it lightweight and easy to carry.

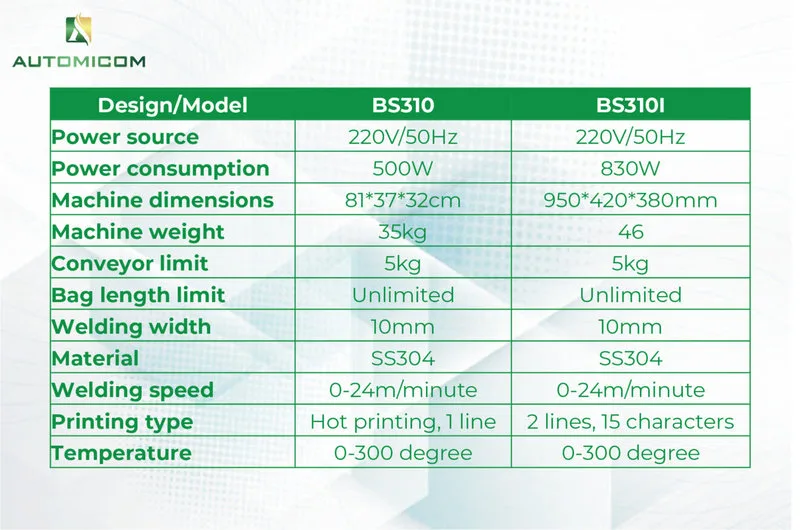

Continuous Horizontal Bag Sealing Machine BS310/BS310I

The Automicom BS310/BS310I Continuous Horizontal Bag Sealing Machine is used for sealing bags or packaging horizontally. It utilizes a heated strip to melt the edges of the bag together, creating a tightly sealed line. The BS310 machine is commonly used in the packaging industry for food and beverages, pharmaceuticals, and cosmetics.

The machine operates by passing the bag or packaging through a conveyor, then moving them through the sealing strip. First, the strip heats to a high temperature, and pressure applies to the bag, melting the plastic and forming a secure sealed line. Next, the conveyor moves the sealed bag or packaging out of the machine onto a collection table.

The Automicom Continuous Horizontal Bag Sealing Machine suits packaging and sealing with medium to high productivity. Moreover, it works well with various types of bags such as polyethylene, smooth bags, sandbags, silver bags, and aluminum bags in different sizes.

The BS310 series machines feature durable and sturdy stainless steel SS304 construction. Additionally, the conveyor measures 15-25 cm wide, with adjustable speed and size to accommodate the desired bag. The conveyor supports weights up to 5 kg, allowing you to seal heavy bags such as noodle bags, pasta bags, and grain bags. Finally, the BS310 series comes in two types: one seals bags and offers printing options with various effects depending on the chosen printing wheel, including embossing and strip printing. However, if you want to print ink, you can choose the BS310I machine.

Advantages of the BS310/BS310I Continuous Horizontal Bag Sealing Machine:

- The conveyor speed can be adjusted and extended to fit various packaging sizes.

- The working speed of the BS310 machine is more than 5 times faster than regular bag sealing machines.

- The sealing strip width is up to 10mm, providing a tight and secure packaging.

- Temperature control up to 300°C, capable of sealing bags with a thickness of up to 0.8mm.

- Printing function available for production date, expiration date, etc.

- The machine body is made of stainless steel, durable, and corrosion-resistant.

- Temperature and speed control screen.

- Two types of machines: BS310 (date printing or embossed date printing) and BS310I (date printing with ink roller).

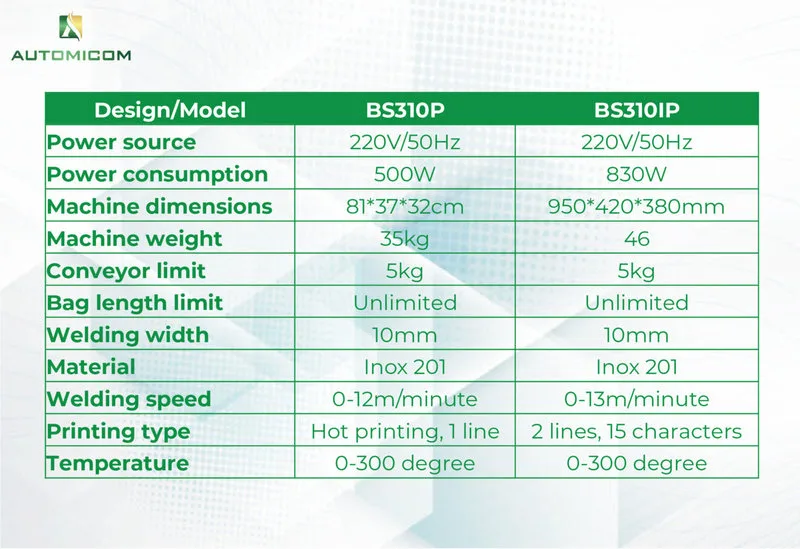

Continuous Horizontal Bag Sealing Machine BS310P/BS310IP

With the BS310P/BS310IP series of machines, the functions and purposes are similar to the BS310/BS310I. The machine has several improvements compared to other types of machines on the market, such as an unlimited length of the sealing line. The machine can operate continuously without consuming too much effort and time. In a day, it can produce a large quantity of products, well-suited to fulfill both large and small orders for companies or manufacturing workshops to achieve the highest revenue. The machine is also divided into two types: one without ink printing (BS310P) and one with ink printing (BS310IP). However, with this series, the machine body is made of electrostatically painted aluminum. Therefore, the cost for this series is also more affordable.

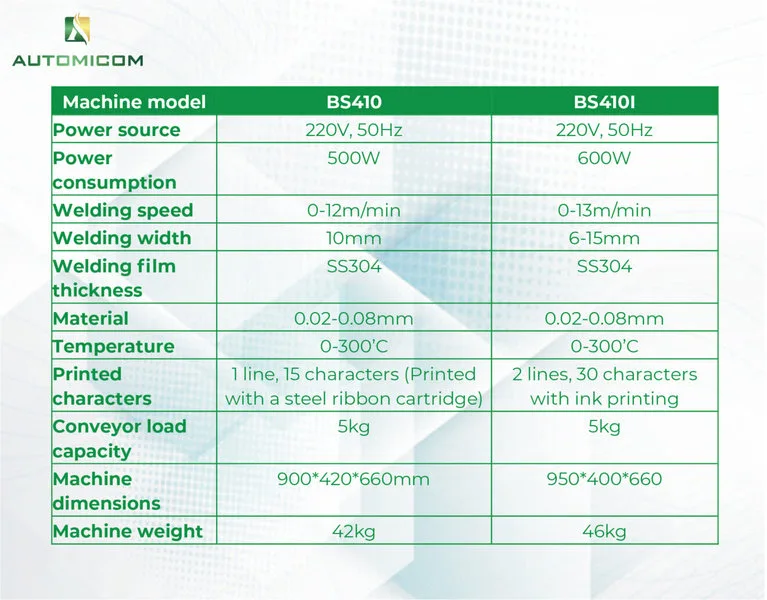

Continuous Vertical Bag Sealing Machine BS410/BS410I

The BS410/BS410I series of continuous vertical bag sealing machines from Automicom are packaging machines used to seal bags or packaging vertically. Specifically, the machine uses a heated strip to bond the edges of the bag together, creating a tight sealing strip. Additionally, the BS410/BS410I series is commonly used in the packaging industry for food and beverages, pharmaceuticals, and cosmetics.

The machine feeds the bag or packaging through a set of rollers and moves them across the sealing strip. The strip heats to a high temperature while applying pressure to the bag, melting the plastic and creating a secure sealing strip. Then, the rollers push the sealed bag or packaging out of the machine onto a collection table. The BS410 series uses durable and sturdy SS304 stainless steel for its construction.

The conveyor belt spans 15–25 cm in width, and you can adjust its speed and size to match the bags you need to seal. It supports bags weighing up to 5 kg, making it easy to seal heavy items like rice bags or liquid sauce packs. The BS410 series comes in two types: one seals bags and prints information with various printing effects depending on the chosen print wheel, including embossing and strip printing. If you need to use ink, you can select the BS410I model.

Our BS410/BS410I continuous vertical bag sealing machines incorporate advanced technology and superior features to meet your business’s packaging needs. Thanks to its continuous sealing ability, the machine creates secure seals and neat packaging, keeping products fresh and ensuring safe transportation.

Advantages of the BS410/BS410I continuous vertical bag sealing machine:

- You can adjust the conveyor belt’s speed and extend it to fit various packaging sizes.

- The machine’s working speed is more than 5 times faster than other types of machines.

- The sealing strip width is up to 10mm, ensuring tight and secure packaging.

- Temperature control up to 300°C, capable of sealing bags with a thickness of up to 0.8mm.

- Printing function available for production date, expiration date, etc.

- The machine body uses stainless steel, offering durability and corrosion resistance.

- Temperature and speed control screen.

- Two machine types: BS410 (printing date submerged or embossed date) and BS410I (printing date with ink).

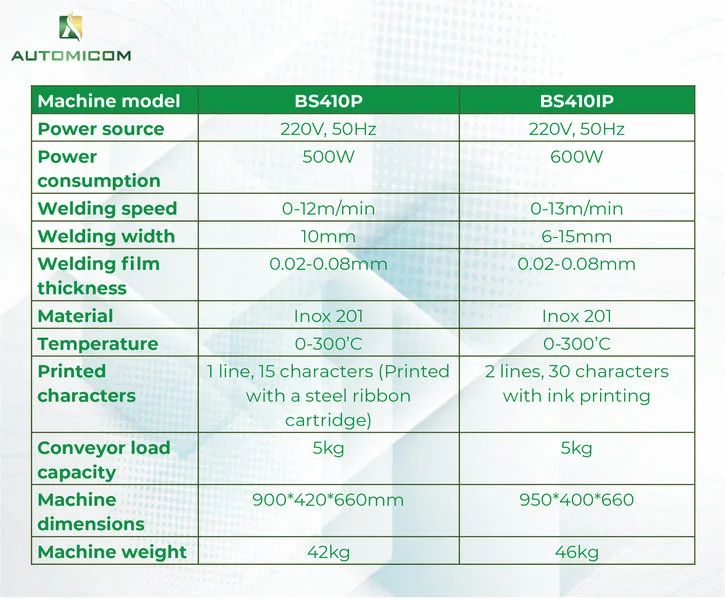

Continuous Vertical Bag Sealing Machine BS410P/BS410IP

The BS410P/BS410IP series of continuous vertical bag sealing machines seal bags vertically with ease. Their sturdy, vertical structure supports sealing bags filled with products prone to spillage, such as granular or liquid items, or overfilled packaging. Unlike horizontal bag sealing machines, this vertical design handles these tasks efficiently. Additionally, the machine automatically adjusts the temperature to deliver even and quick sealing, creating a clean, attractive seal line. The robust frame lifts or lowers to fit different bag sizes. Furthermore, the sealing part uses high heat-conducting copper to ensure optimal heat transfer. The rapid cooling system quickly cools the sealed edge, preventing overheating and bag distortion.

Moreover, the machine integrates emboss printing to mark the production date and expiration date directly on the sealing line. However, the BS410P series does not support ink printing, whereas the BS410IP series does. Finally, compared to the BS410/BS410I series, these machines feature a powder-coated aluminum body, which reduces costs without compromising durability.

Foot Pedal Continuous Bag Sealing Machine PFS-F450/PFS-F600/PFS-F800

Automicom’s foot pedal continuous bag sealing machine seals bags and pouches using a foot pedal. Place the bag between the heating element and clamping bar, press the foot pedal to heat and seal the plastic, then release the pedal to remove the sealed bag.

Our foot pedal sealing machine simplifies the bag sealing process and significantly enhances work efficiency. With the foot pedal operation, you don’t need to use your hands, which allows easy positioning and adjustment of packaging materials to achieve a consistent, tight seal.

Moreover, Automicom’s PFS series machines use high-quality materials to ensure durability and long-lasting performance. The sealing width reaches up to 1 cm, and a spring mechanism enables efficient and rapid sealing of multiple bags or continuous packaging materials. The sturdy construction provides reliable performance, even under heavy use.

Additionally, the PFS-F450, PFS-F600, and PFS-F800 models offer sealing lengths of 45, 60, and 80 cm, respectively, to accommodate a wide range of bag sizes and packaging needs.

Therefore, foot pedal sealing machines suit industries such as food and beverages, pharmaceuticals, and cosmetics. They work well for small businesses or those with limited space because they occupy less area than larger models. Furthermore, the PFS series machines offer a cost-effective solution without compromising quality.

In conclusion, the hands-free operation allows users to multitask during sealing, and the machine’s flexibility in handling different bag types makes it an excellent choice for various packaging applications. Overall, Automicom’s foot pedal sealing machines improve packaging speed and quality, making them essential for businesses aiming to optimize their packaging process.

Machine Specifications

Common Issues of Bag Sealing Machines and Solutions

Incomplete or Torn Bag Sealing:

– The cause of this issue is unevenness in the machine’s sealing bar, resulting in an inaccurate and incomplete seal. Additionally, an overly sharp seal may cause the bag to tear when moving on the conveyor. Adjusting the sealing bar to be flat and aligned can address this issue. Moreover, It is essential to avoid excessively sharp seals by adjusting the temperature according to the bag’s thickness. If the sealing bar shows damage, replace it promptly to maintain accurate and high-quality bag sealing.

Unstable Bag Sealing Temperature:

– Continuous bag sealing machines usually have a sensor system to determine the precise temperature for operation. However, inaccurate temperature control or unstable sensors can lead to temperature fluctuations.

– To troubleshoot this error, ensure the availability of replacement components such as the temperature display board and machine sensors. Testing is necessary to identify the faulty part before replacement.

Power Disconnection Issues:

– This problem often occurs when you overload the bag sealing machine or leave it unused for a long time. The issue may stem from damaged power cables or electrical transmission switches.

– To address this problem, check the machine’s power path to the outlet for any issues, especially breaks or loose connections. Defective electrical switches are easily replaceable with alternative switches.

Conveyor Malfunction:

– Conveyor malfunctions may have various causes. First, dirt, obstructions, or worn-out gears can jam the machine’s gear system. Additionally, conveyor issues may arise from a worn or broken belt or blockages.

– To rectify this problem, regularly clean the machine and lubricate its working motor. Replace damaged gears and worn-out belts promptly.

Incomplete Sealing After Sealing:

– This issue often happens when you don’t carefully adjust the packaging placement on the heat-sealing line. Misalignment can cause uneven pressure, resulting in some areas of the seal becoming too narrow and others failing to seal properly.

– Other causes include a slow conveyor speed combined with excessively high temperature causing the bag to shrink or burn. Conversely, a too-fast conveyor speed may not allow the sealing machine sufficient time to completely seal the bag.

– To address this issue, adjust the bag during the bag sealing machine operation to ensure it is flat for both handheld and continuous bag sealing machines. Press both sides of the handheld bag sealing machine tightly to ensure full contact of the sealing line with the bag opening. Moreover, observe the continuous automatic bag sealing machine’s sealing process to timely adjust positions of shrunken or burnt bags. Pay attention to adjusting the speed and temperature to match the machine and bag.

Blurry Ink Printing on Continuous Bag Sealing Machine with Date Printing:

Blurry ink printing may result from misalignment of the date printing character attachment or wear on the ink ribbon of the date-printing bag sealing machine. Therefore, to resolve this issue, check the characters and thermal ink to adjust or replace them. Also, pay attention to and adjust the date printing time to match the bag material, avoiding cases where the bag is too thick and does not have enough time for date printing.