Subtotal: $2,200.00

Who Uses Dehydrator Machines?

Home users typically use food dehydrators to prepare healthy snacks and homemade ingredients without preservatives. Common uses include drying fruits, vegetables, herbs, and meat for personal consumption.

Small businesses rely on dehydrator machines to produce food products in consistent batches while keeping investment costs manageable. These users often include:

- Small food brands

- Home-based food businesses

- Cafés and speciality shops

- Health food and snack producers

Food factories and processors use industrial dehydrator machines for large-scale and continuous production. These systems are designed for:

- High throughput

- Uniform drying results

- Long operating hours

- Food safety compliance

TYPES OF DEHYDRATORS

Home Use Dehydrators (6–16 Trays)

Home use dehydrators are compact food dehydrators designed for personal kitchens and small-scale food preparation. These machines are ideal for families, hobby users, and health-conscious consumers.

Key features:

- 6 to 16 stainless steel (SS) trays

- Temperature range up to 90°C

- Compact and space-saving design

- Food-grade stainless steel trays

- Easy digital temperature and timer control

Common uses:

- Fruit and vegetable dehydration

- Herbs and spices

- Homemade snacks and jerky

Home dehydrators are popular as entry-level dehydrator machines for users who want consistent drying results without complex operation.

Semi-Industrial Dehydrators (16–32 Trays)

Semi-industrial dehydrators are designed for small businesses that need higher output while maintaining flexibility. These food dehydrators bridge the gap between home use and full industrial production.

Key features:

- 16 to 32 stainless steel trays

- Higher drying capacity per batch

- Improved airflow for uniform drying

- Continuous daily operation capability

- Easy cleaning and maintenance

Typical users:

- Small food manufacturers

- Home-based food businesses

- Cafés and speciality snack producers

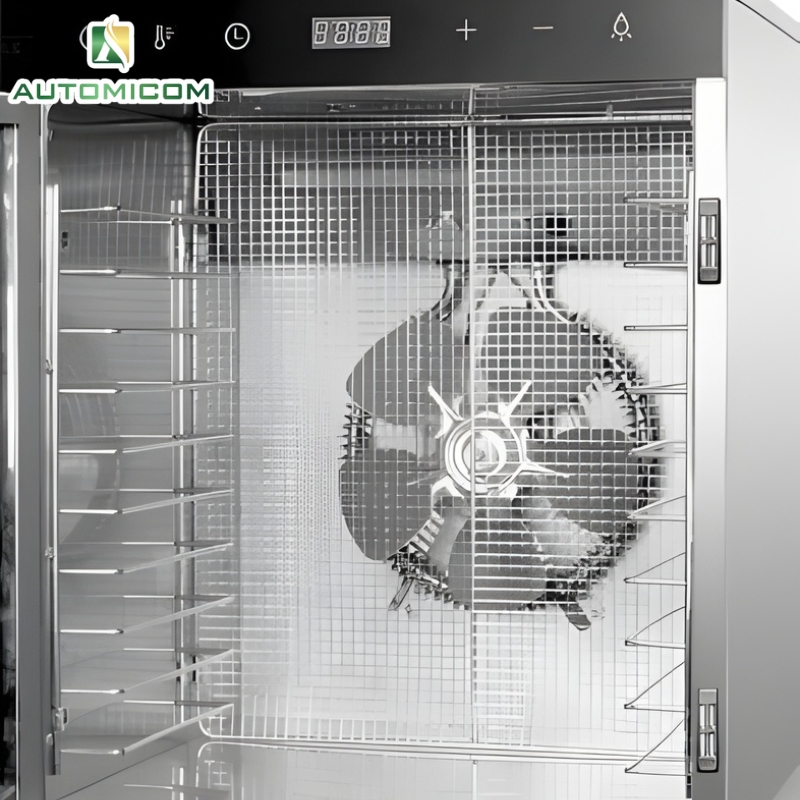

Industrial Dehydrators (Up to 60 Trays – Standing Design)

Industrial dehydrators are high-capacity dehydrator machines designed for commercial food production and factory use. These systems are built for durability, efficiency, and long operating hours.

Key features:

- Up to 60 trays or more

- Standing cabinet design with heavy-duty construction

- Multiple high-performance fans for even airflow

- Advanced temperature and airflow control systems

- High drying efficiency for fruits, vegetables, meat, and herbs

- Suitable for continuous production environments

Industrial food dehydrator systems ensure consistent quality and high throughput.

How a Dehydrator Machine Works

A dehydrator machine is designed to remove moisture from food using controlled heat and airflow. By slowly drying food at low temperatures, a food dehydrator helps preserve flavour and nutrients while significantly extending shelf life.

Working Process of a Food Dehydrator

1. Gentle Heating: The dehydrator uses an electric heating element to generate warm air, typically between 35°C and 80°C, depending on the food type. This low-temperature drying prevents cooking or burning while protecting vitamins and natural enzymes.

2. Even Air Circulation: A built-in fan circulates heated air evenly across all trays inside the dehydrator machine. Uniform airflow ensures consistent drying across all levels, eliminating wet spots and uneven results.

3. Moisture Removal: As warm air passes over the food, moisture slowly evaporates and is expelled through ventilation outlets. This controlled dehydration process reduces water activity, preventing mold growth and bacterial spoilage.

4. Adjustable Time and Temperature: Food dehydrators allow users to adjust drying time and temperature based on the product: Fruits and vegetables, Meat and seafood, Herbs and spices, Pet treats and speciality foods.

Why Dehydration Preserves Food Effectively

Removing moisture:

Extends shelf life naturally (no preservatives needed)

Retains original taste and aroma

Reduces weight and storage space

Maintains nutritional value better than high-heat drying methods

Therefore, a dehydrator machine is widely used in food processing, health food production, and pet food manufacturing.

WHY CHOOSE AUTOMICOM DEHYDRATOR?

Designed for Consistent Drying Results

Our dehydrator machines use optimised airflow and precise temperature control to ensure uniform dehydration across all trays or chambers. This consistency is critical for food quality, shelf life, and repeatable production, especially in vegetable dehydrator and food processing applications.

- Even heat distribution

- Stable temperature control

- Reliable moisture removal

Food-Grade & Hygienic Construction

All our food dehydrators are built with food-grade stainless steel, making them safe, durable, and easy to clean. Hygienic design helps prevent contamination and supports compliance with food safety standards.

- Stainless steel trays and interior

- Easy-to-clean surfaces

- Suitable for commercial food production

Scalable Solutions for Every Production Size

We offer a complete range of dehydrator machines to match different production needs:

- Compact dehydrators for home use

- Semi-industrial models for small businesses

- Industrial and rotary dehydrators for large-scale processing

Professional Support

We support our customers beyond the sale by offering:

- Model selection guidance

- Capacity and application recommendations

- Technical support and spare parts availability

One Dehydrator Solution for Every Scale

Whether you need a compact dehydrator for home use, a reliable food dehydrator for a growing business, or a high-capacity dehydrator machine for factory production, choosing the right system depends on:

- Daily output requirements

- Product type (fruit, vegetables, meat, herbs)

- Available space

- Energy efficiency goals

OUR SUCCESS STORIES

SMALL BUSINESS | Chicken Wing Dog Treats

Rotary Dehydration for Herb Processing Factory

Frequently Asked Questions

1. What types of food can be dried using a dehydrator machine?

Our dehydrator machines are suitable for a wide range of foods, including fruits, vegetables, herbs, meat, seafood, and pet food products. From home fruit drying to industrial ginger and meat dehydration, each model is designed to deliver consistent and reliable results.

2. How do I choose the right dehydrator for my needs?

The right dehydrator depends on your daily output and application. Home users typically choose compact models with 6–16 trays, small businesses use semi-industrial dehydrators with higher capacity, and food factories require industrial or rotary dehydrator machines for continuous operation. Our team can help recommend the best option.

3. Are your dehydrator machines made of food-grade materials?

Yes. All our food dehydrators are constructed with food-grade stainless steel for durability, hygiene, and easy cleaning. This ensures safe food processing and long-term reliability for both home and commercial use.

4. Can the dehydrator machine operate continuously for daily production?

Our semi-industrial, industrial, and rotary dehydrator machines are designed for continuous daily operation. With proper maintenance, they provide stable performance for long working hours, making them suitable for small businesses and food processing factories.

5. Do you provide technical support and spare parts after purchase?

Yes. We provide local technical support, maintenance services, and spare parts availability. Our after-sales support ensures minimal downtime and long-term confidence when using our dehydrator machines.

Semi Industrial Dehydrator (32 trays) (DH32)

Semi Industrial Dehydrator (32 trays) (DH32)