No products in the cart.

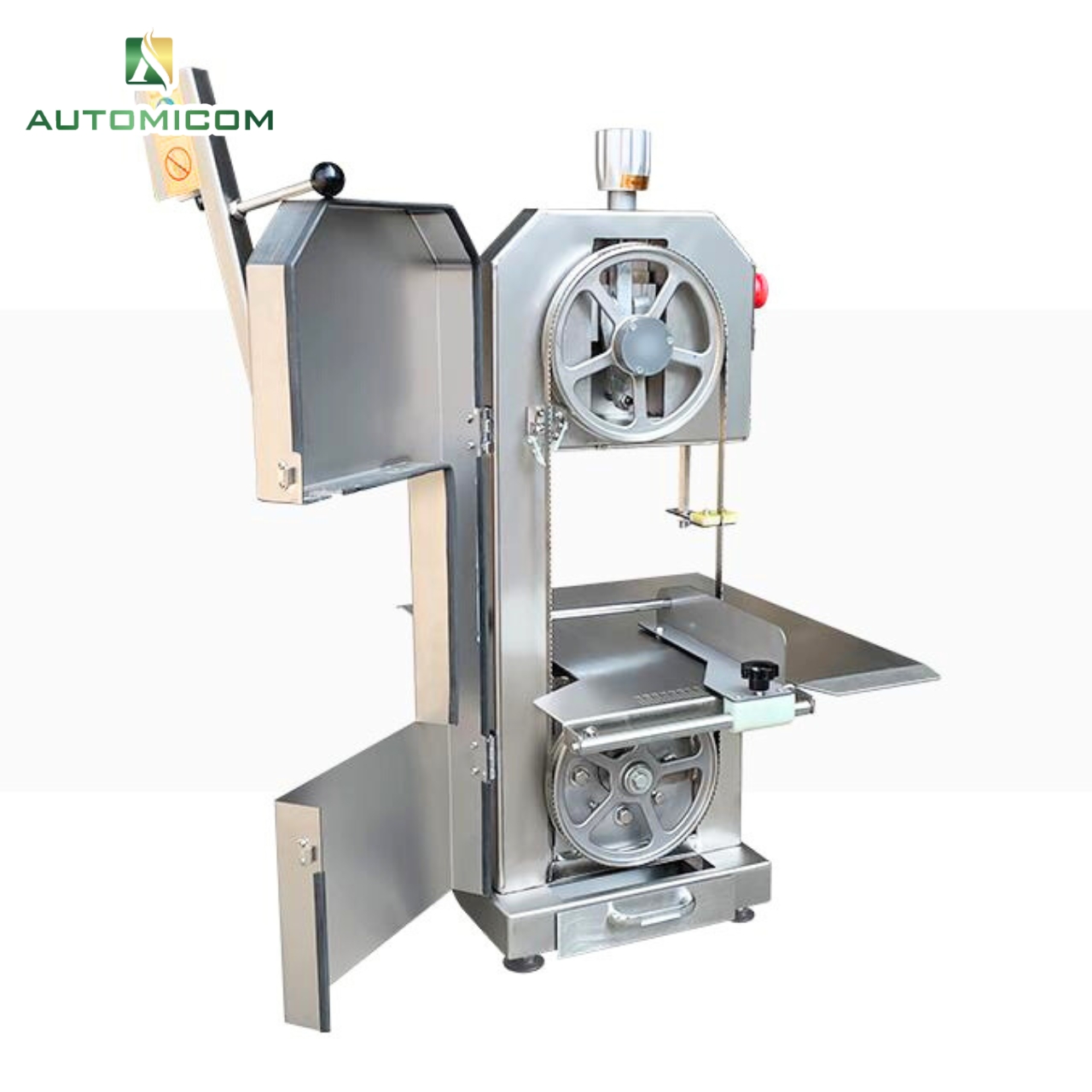

Industrial Bone Saw (BS310AH and BS350AH)

Contact for price

- Durable Construction: Made from high-quality stainless steel for long-lasting performance.

- Powerful Motor: Efficiently handles frozen meat blocks.

- Precision Cutting: Sharp blades ensure uniform meat cubes; adjustable cutting size.

- Easy Operation: Simple control panel and loading process.

- Safety First: Includes safety guards and automatic shut-off.

- Low Maintenance: Removable parts for easy cleaning.

INTRODUCTION OF INDUSTRIAL BONE SAW

An Industrial Bone Saw Machine is a highly versatile and essential tool, particularly in the food processing industry, where cutting through bones, frozen meats, and other tough materials is a common requirement. Not only does this machine provide efficiency, but it also ensures precision, making it indispensable in various settings. For instance, butcher shops, meat processing plants, and seafood facilities heavily rely on these machines due to their ability to deliver clean, consistent cuts. Moreover, the durable construction with stainless steel and powerful motor of an Industrial Bone Saw Machine guarantee optimal performance while minimizing material waste, further enhancing its value.

On the other hand, the term Bone Cutting Machine is often used interchangeably with Industrial Bone Saw Machine to refer to these high-performance devices. Furthermore, a Bone Cutting Machine is specifically designed to handle heavy-duty tasks, such as cutting large bones, segmenting carcasses, and slicing frozen products. Additionally, these machines come equipped with advanced safety mechanisms and easy-to-clean components, which not only prioritize operator safety but also ensure hygiene standards are maintained. Therefore, whether referred to as an Industrial Bone Saw Machine or a Bone Cutting Machine, these tools play a critical role in professional kitchens and industrial food processing facilities, offering both reliability and versatility.

SPECIFICATIONS OF INDUSTRIAL BONE SAW

| Product Specifications | ||

| ModelBS | BS310AH | BS350AH |

| Voltage | 220/380V-50Hz | 220/380V-50Hz |

| Power | 0.50 kg | 0.50 kg |

| Waterproof type | 1px1 | 1px1 |

| Pulley diameter | 0.40 m m | 350m m |

| Saw blade length | 2000m m | 2420M M |

| Cutting height | 300m m | 350m m |

| Desk size | 690*545m m | 760mm * 640m m |

| Product size | 780*750*1500m m | 850*670*1660m m |

| Product weight | 80kg | 98kg |

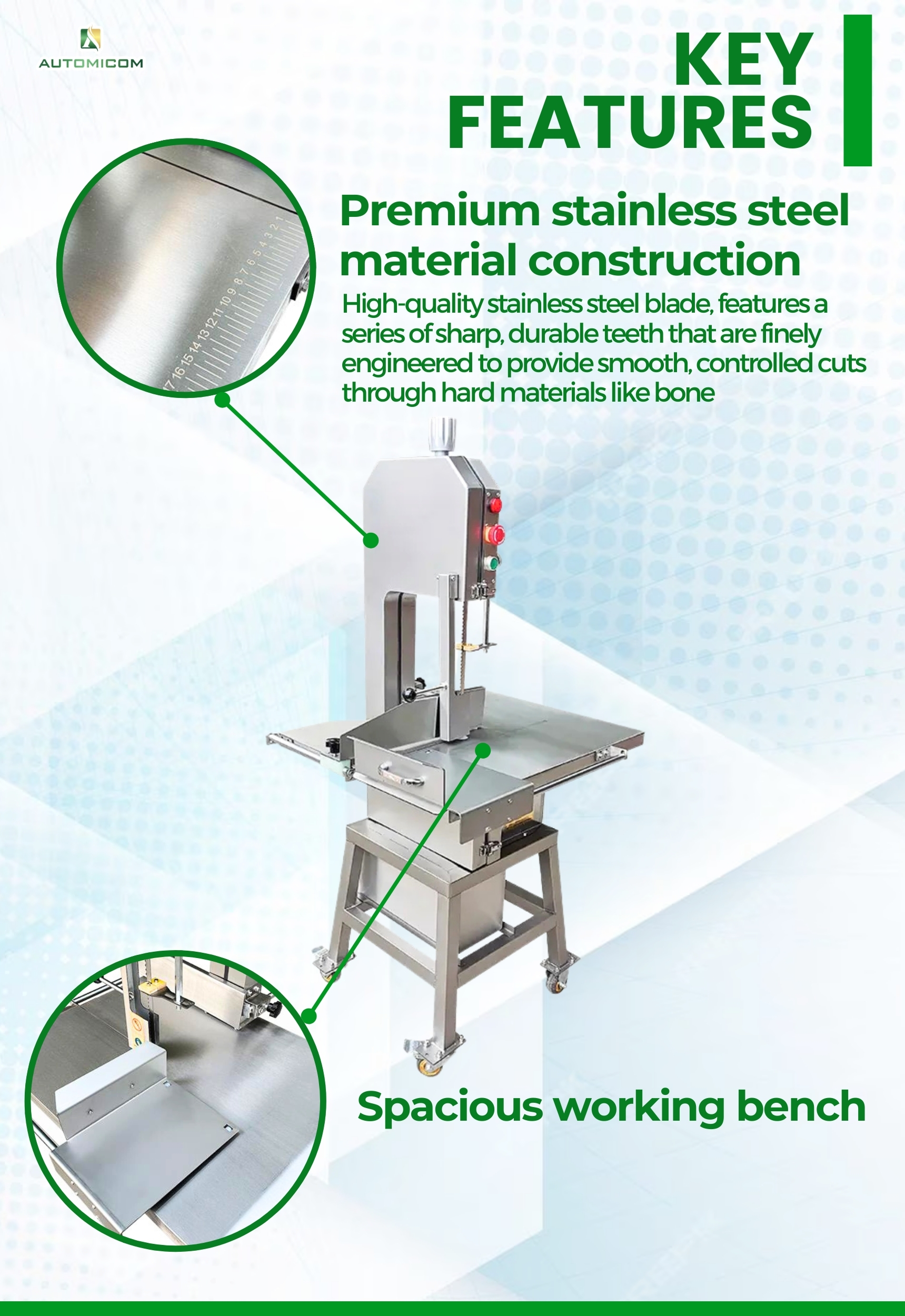

KEY FEATURES OF INDUSTRIAL BONE SAW

Powerful Performance

The robust 1100W/1500W motor ensures quick and efficient processing of various bone types, delivering powerful performance. Furthermore, it enables smooth and consistent operation, even during high-demand tasks, ensuring efficiency. As a result, it reduces processing time, making it an essential tool for busy establishments.

Durable Build

Made from high-quality materials, the machine is built to withstand heavy-duty use, ensuring long-lasting reliability in demanding environments. Additionally, its durable construction reduces the risk of wear and tear, supporting continuous operation. Consequently, businesses can rely on its performance for years, even under tough conditions.

Precise Cutting

This machine is equipped with a sharp, durable blade, which ensures clean, consistent cuts for accurate portioning. Moreover, it reduces waste by providing uniform portions, enhancing both efficiency and presentation. As a result, it improves performance, even in high-volume operations, where precision is crucial.

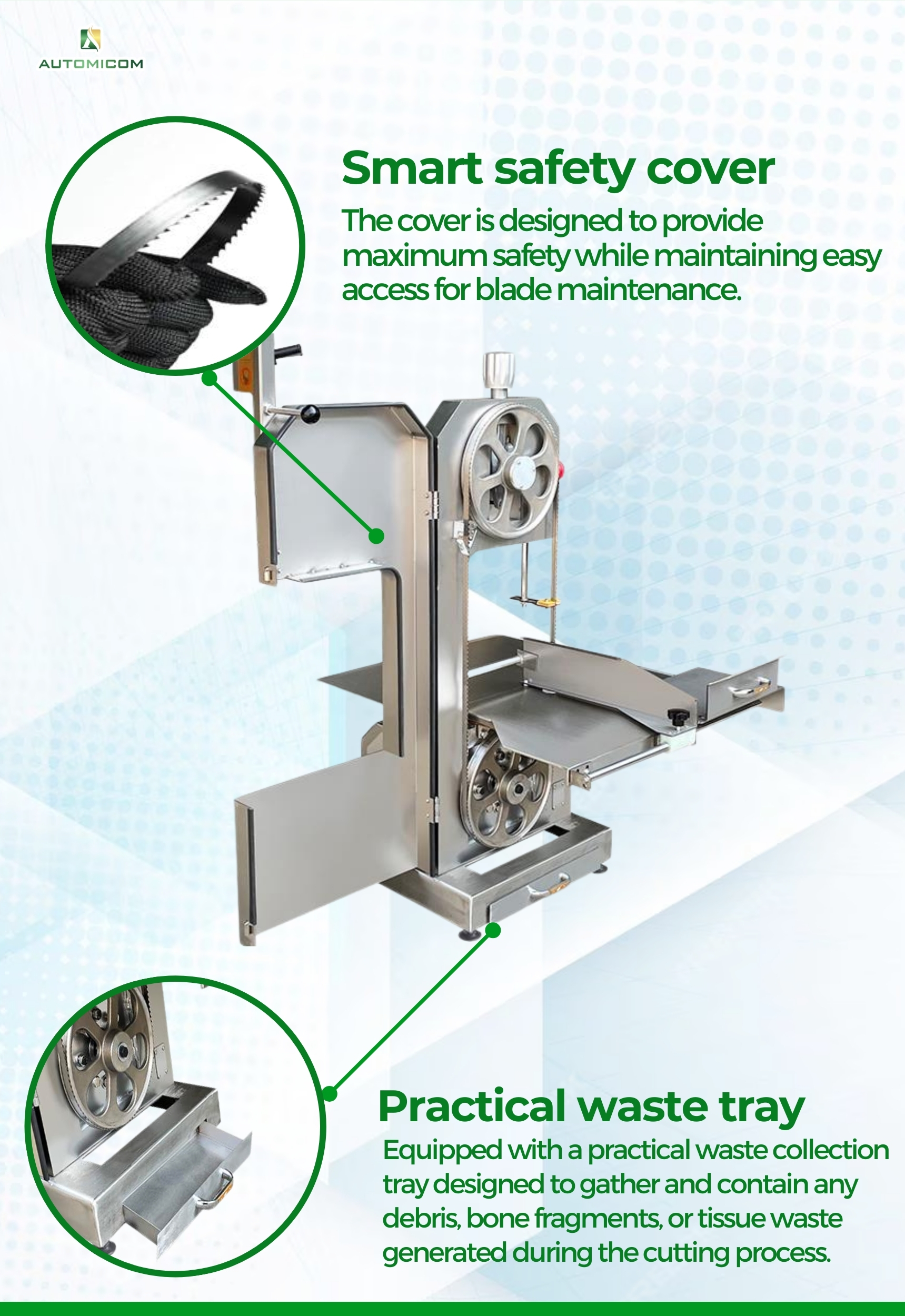

Safety First

The machine prioritizes operator protection by including a safety switch to prevent accidental start-ups.

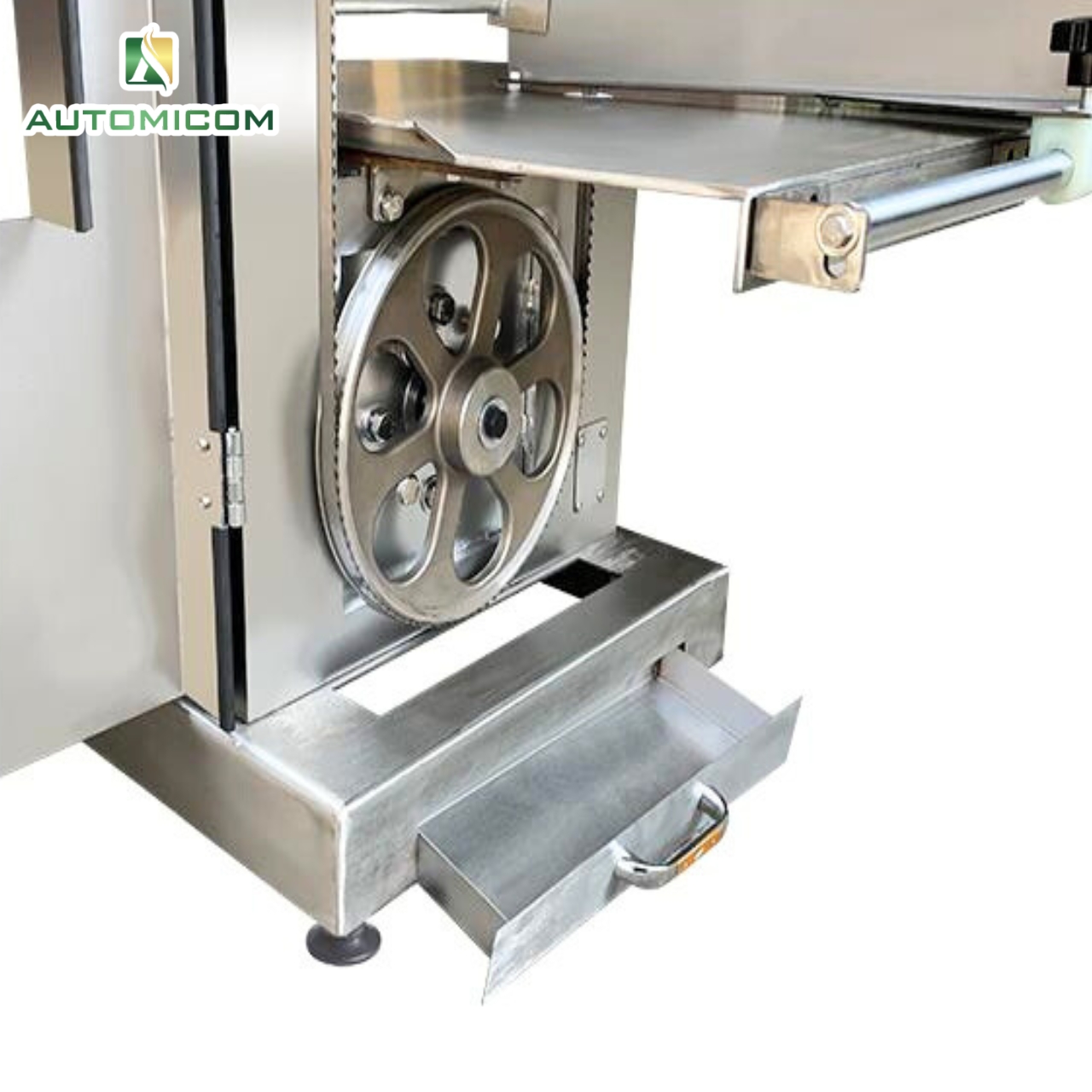

Easy Maintenance

With smooth surfaces, the machine simplifies cleaning and helps maintain a hygienic workspace. Furthermore, its removable parts allow for easy maintenance, which reduces downtime and keeps the machine in top condition. Consequently, the design ensures long-term reliability and efficient operation.

Versatile Use

This machine is highly versatile, capable of cutting bones, frozen meat, fish, and similar products with precision. In addition, its adaptability makes it ideal for a variety of food processing tasks, meeting the diverse needs of different industries. Thus, it enhances operational flexibility and efficiency across multiple applications.

CLOSER LOOK OF INDUSTRIAL BONE SAW

APPLICATIONS OF INDUSTRIAL BONE SAW

Meat Processing in Butcher Shops

Industrial bone saw machines are essential in butcher shops for processing large cuts of meat like beef, pork, and lamb. These machines efficiently cut through thick bones and dense tissues, ensuring clean and precise portions. As a result, this precision enhances product presentation and simplifies packaging for retail and wholesale.

Seafood Processing

In seafood processing, bone saw machines are crucial for tasks like cutting through frozen fish, fish heads, and hard shells. By delivering clean and accurate cuts, they ensure the quality and consistency of seafood products. This, in turn, helps processors meet industry standards and satisfy customer expectations.

Frozen Meat Cutting

Bone saw machines are vital in food processing plants for slicing frozen meats. With powerful motors and sharp blades, they ensure precise cuts, reducing manual labor. Furthermore, they increase operational efficiency, streamlining large-scale production processes.

Poultry Processing

In poultry processing, bone saws easily cut through bones and segment large birds like turkeys and chickens. This creates uniform portions for packaging and bulk sales, ensuring consistency.

Pet Food Production

Bone saw machines break down bones and meats for pet food formulations, ensuring precise sizing while meeting hygiene standards for safety.

| Bone Saw | BS310AH, BS350AH |

|---|

1 year warranty

1. What types of materials can the industrial bone saw cut?

The industrial bone saw is designed to cut through various tough materials, including large bones, frozen meat, and fish. Its powerful motor and durable blade ensure smooth and precise cuts, making it suitable for high-volume meat processing operations.

2. How do I clean and maintain the bone saw machine?

To maintain the bone saw machine, regularly clean the stainless steel body, working table, and blade with food-safe cleaning agents. The machine is designed with easy-to-remove parts, including the food residue tray, for quick and thorough cleaning. Routine inspections and annual preventive maintenance are recommended to ensure optimal performance and longevity.

3. Is the machine safe to operate?

The machine has several safety features, including safety guards around the blade and emergency stop buttons. The sturdy floor-standing design also ensures stability during operation. Operators should be trained on proper usage and follow all safety guidelines provided in the user manual.

Reviews

There are no reviews yet.