Subtotal: $2,200.00

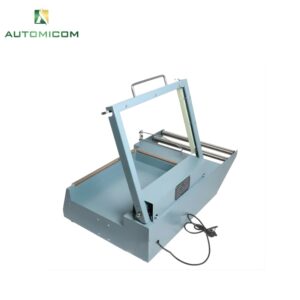

L Bar Cutter (LB100)

$650.00

- Simple operation with a compact, space-saving structure

- Accurate sealing and cutting based on actual product size

- Compatible with shrink tunnels for complete shrink packaging

- Able to operate independently for flexible packaging needs

- Heat-resistant, anti-adhesive sealing cutter for even and secure seals

Contents

ToggleL BAR CUTTER (LB100)

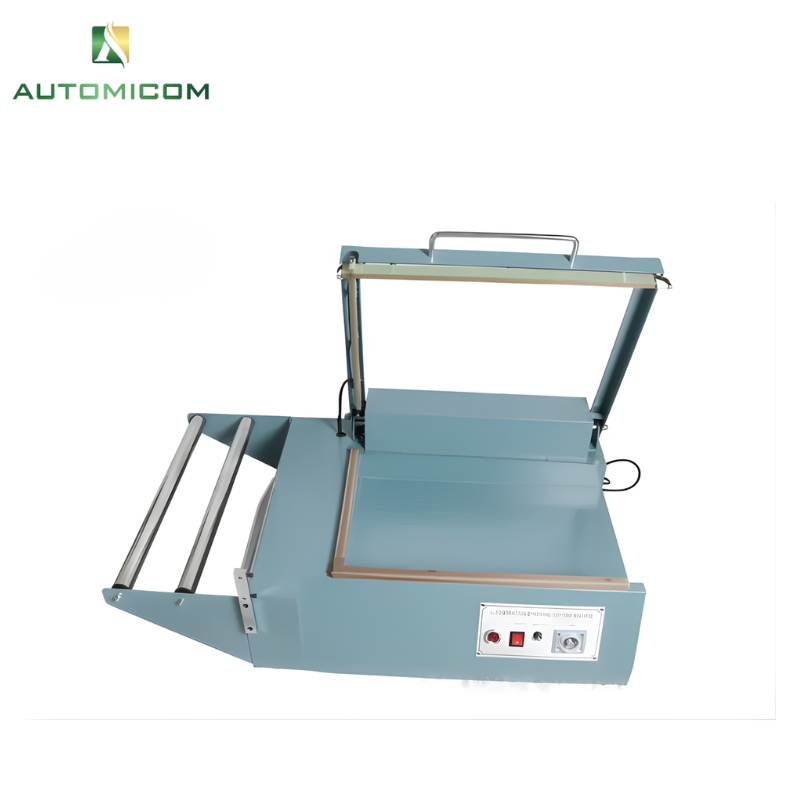

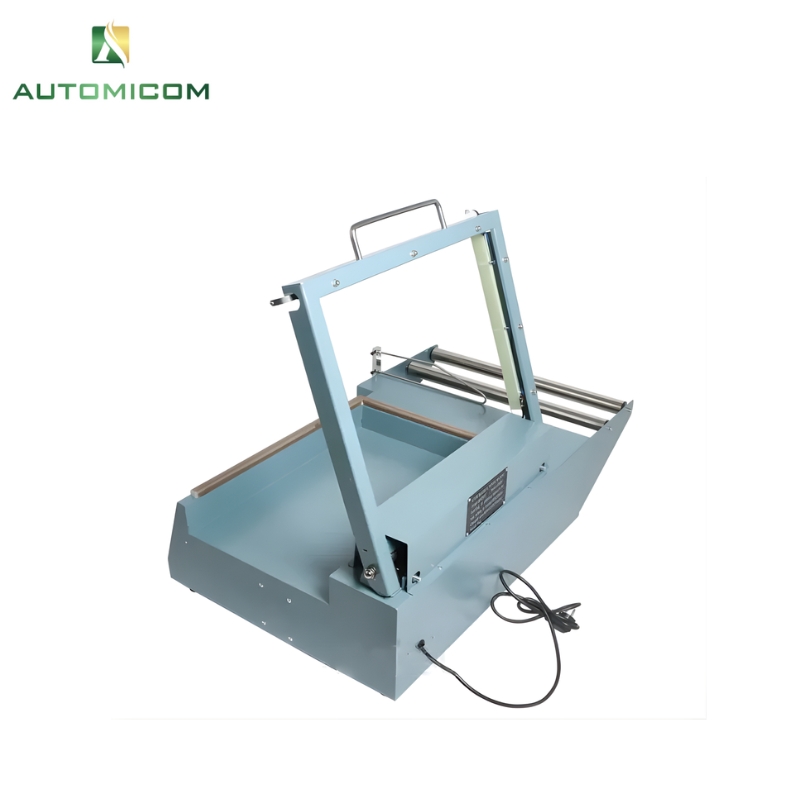

INTRODUCTION OF L BAR CUTTER

The L bar cutter is a high-quality L-type sealing and cutting machine designed for efficient shrink film packaging. First, this L bar cutter allows operators to place products into shrink film and apply pulse fusion sealing and cutting to achieve accurate loose packaging. Next, the sealed items move to a heat shrink machine, where infrared heat creates a tight and professional finish. Moreover, the L bar cutter works as a front-end solution in shrink packaging lines and integrates smoothly with shrink sealing and heat shrink machines.

Meanwhile, the Mini L bar cutter delivers the same reliable sealing and cutting performance in a compact structure. Additionally, the Mini L bar cutter suits small to medium operations that require space efficiency without sacrificing quality. Finally, both the L bar cutter and Mini L bar cutter include a roll holder rack to ensure stable film feeding, consistent sealing results, and reduced material waste.

SPECIFICATIONS

| Model | LB100 |

| Speed | 0–3 s / cut |

| Pack size | W350 × L500 mm |

| Voltage | 110 / 220–240 / 380–420 V, 50–60 Hz |

| Power | 1 kW |

| Machine weight | 30 kg |

KEY FEATURES OF L BAR CUTTER

Simple Operation and Compact Structure

First, the L bar cutter features a user-friendly operating system and a compact structure that saves space and simplifies installation. The Mini L bar cutter is especially suitable for small production areas while maintaining the same operational efficiency.Accurate Sealing and Cutting Based on Product Size

Next, operators place each product into the shrink film, and the product seals and cuts the film precisely according to product dimensions. This accurate cutting method reduces film waste and ensures clean, professional packaging results.Flexible Standalone or Integrated Operation

Meanwhile, It works smoothly with a shrink tunnel to complete the full shrink packaging process. It can also operate independently for loose packing, offering flexible use across different packaging needs.Heat-Resistant and Anti-Adhesive Sealing Cutter

Moreover, the L bar cutter uses a heat-resistant, anti-adhesive coated sealing blade that delivers even, secure seals while preventing film sticking and burn marks.Stable Performance and Reliable Output

Finally, both the L bar cutter provide stable performance during continuous operation, ensuring consistent sealing quality and improved packaging efficiency.

CLOSER LOOK

APPLICATIONS

Food Packaging

First, It prepares food products such as snacks, bakery items, frozen foods, and daily consumables for shrink packaging. It seals and cuts shrink film accurately before products enter a shrink tunnel, ensuring hygienic, secure, and consistent packaging results.Cosmetics and Personal Care Products

Next, the bar is commonly used for packaging cosmetics, skincare products, soaps, and personal care items. This application improves shelf appearance and protects products during storage and transportation.Electronics and Hardware Items

Meanwhile, It packages electronic accessories, small devices, tools, and hardware components. The shrink film wrapping helps protect items from dust, moisture, and minor handling damage.Pharmaceutical and Medical Products

Moreover, the product cutter supports the packaging of boxed medicines, medical devices, and healthcare supplies. It delivers clean, reliable seals suitable for professional and tamper-evident packaging.Retail, Stationery, and Promotional Goods

Finally, both the product are ideal for bundling books, stationery, gift sets, and promotional items, creating an organized and attractive product presentation.

FIND OTHER SEALING MACHINE: LINK!!!

1 year warranty

- What types of shrink film can the L bar cutter use?

The L bar cutter works with common shrink films such as POF, PE, and PVC, depending on machine configuration and product requirements. - Can the Mini L bar cutter operate without a shrink tunnel?

Yes, the Mini L bar cutter can work independently for loose packaging, but it is usually paired with a shrink tunnel for tight shrink-wrapped results. - Is the L bar cutter easy to operate and maintain?</strong>&amp;amp;lt;br data-start=”611″ data-end=”614″ />Yes, the L bar cutter features simple controls, quick setup, and low maintenance, making it suitable for both new operators and experienced users.

Be the first to review “L Bar Cutter (LB100)” Cancel reply

KEY FEATURES OF DEHYDRATOR MACHINE (6-16 TRAYS)

Automicom food dehydrator is built with a strong SS201 stainless steel body, providing excellent structural stability and long-term durability. The brushed stainless steel finish gives the machine a clean, professional appearance while remaining easy to maintain.

Inside, the unit features food-grade SS304 stainless steel trays, ensuring safe and hygienic contact when you dehydrate food. The spacious tray design allows you to load more ingredients at once, improving efficiency and maximizing productivity for both home and small business use.

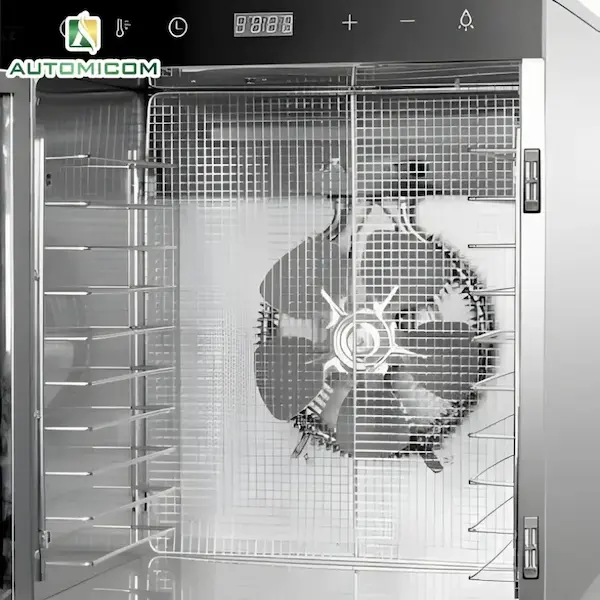

The interior of the dehydrator is designed for maximum capacity and flexibility. Multiple stainless steel trays are neatly arranged to provide ample space for evenly spreading food, allowing efficient airflow between each layer.

The dehydrator features a well-designed rear ventilation for stable and efficient operation. The large circular vent contains a powerful circulating fan that ensures consistent airflow throughout the chamber and preventing overheating and maintaining stable internal temperature during long hours of operation.

A circulating fan system is designed to ensure consistent, uniform airflow throughout the dehydrator's chamber. The rear-mounted fan distributes warm air evenly across all trays, eliminating hot spots and reducing uneven drying.

The optimized airflow system works together with precise temperature control to preserve food texture, color, and nutrients.

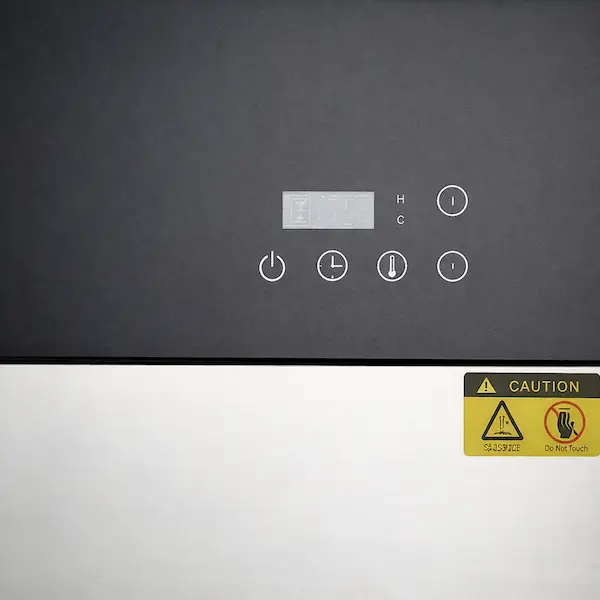

The dehydrator features a simple and intuitive control panel, designed for easy operation. With adjustable temperature control from 30°C to 90°C, you can precisely set the ideal drying condition for fruits, vegetables, herbs, meat, and more.

The built-in 24-hour timer setting allows you to customise drying time according to different food types.

Actual Results from Our Dehydrating Machine

Freshly sliced fruits are evenly dried on stainless steel mesh trays, preserving their natural colour, texture, and flavour. The moisture is carefully removed to create lightweight, long-lasting dried fruits—perfect for healthy snacks, retail packaging, or vacuum sealing for extended shelf life.

Sliced meat is evenly dehydrated to achieve a firm, dry texture while retaining its rich color and natural flavor. Ideal for jerky production or pet treats, the final product has reduced moisture, extended shelf life, and is ready for packaging or vacuum sealing

Fresh ginger, garlic, lemongrass, and chili are evenly dried to preserve their strong aroma and natural flavor. The final dehydrated herbs are lightweight, easy to store, and ideal for grinding into powder, tea blends, spice mixes, or long-term food production

Why choose Automicom Dehydrator?

SELLING PRODUCTS

Dehydrator

Automatic Cup Sealer (CS900)

Automatic Cup Sealer (CS900)

Reviews

There are no reviews yet.