Subtotal: $1,990.00

Semi Industrial Dehydrator (32 trays) (DH32)

$2,200.00

SEMI INDUSTRIAL DEHYDRATOR (32 trays) (DH32)

INTRODUCTION OF SEMI INDUSTRIAL DEHYDRATOR

Our Semi Industrial Dehydrator delivers efficient food drying while preserving nutrients, color, and natural flavor. First, it serves businesses that need higher capacity than household units without moving to full industrial systems. As a result, this Small Industrial Dehydrator suits small factories, farms, and commercial kitchens that demand stable performance at a reasonable cost.

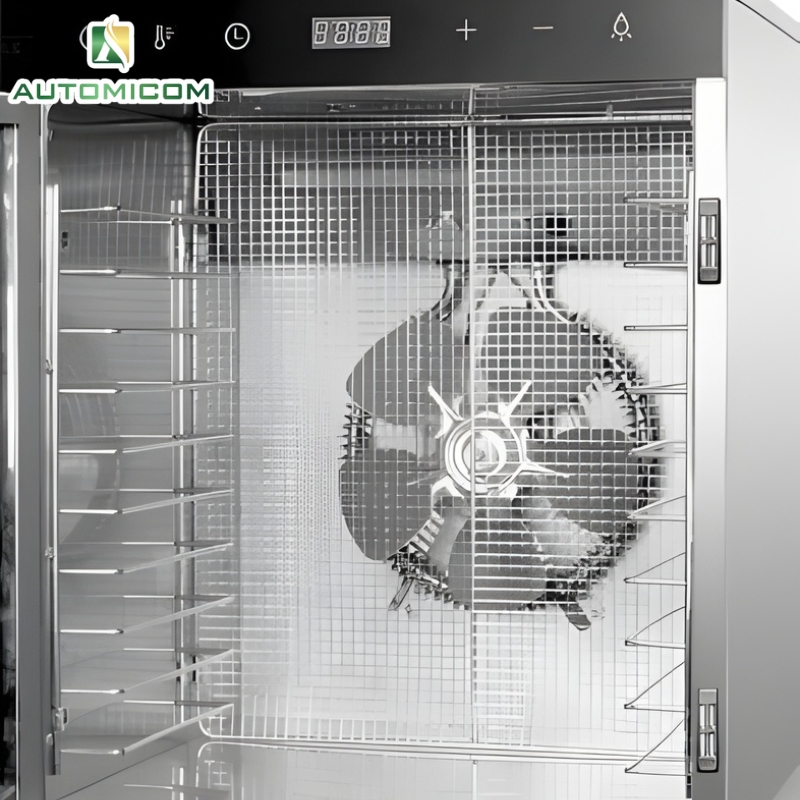

Moreover, the Semi Industrial Dehydrator uses advanced hot-air circulation to distribute heat evenly across all trays. Meanwhile, operators adjust temperature settings to match different products, which improves drying consistency and shortens processing time. Therefore, this Small Industrial Dehydrator helps reduce energy consumption while maintaining strong output.

Finally, with a stainless steel body and multi-tray cabinet design, the Semi Industrial Dehydrator supports long-term use and easy cleaning. Its user-friendly control panel simplifies operation and boosts productivity in daily food processing.

SPECIFICATIONS OF SEMI INDUSTRIAL DEHYDRATOR

| Model | DH32 |

| Voltage | 220V |

| Power consumption | 3000W |

| Temperature range | 30-120C |

| Machine size | 46.8 x 138 x 57 cm |

| Chamber size | 38.5 x 60 x 41.4 cm |

| Machine weight | 46KG |

| Machine body material | SS201 |

| Tray material | SS304 |

| Number of trays | 32 |

| Mesh size | 40 x 38cm, mesh size 0.8 x 0.8 cm, and the spacing between upper and lower layers is 3.5cm |

KEY FEATURES OF SEMI INDUSTRIAL DEHYDRATOR

1. Uniform Hot-Air Drying

This Semi Industrial Dehydrator circulates hot air evenly across all 32 trays. First, it ensures consistent drying results and maintains stable product quality.

2. High-Power Industrial Motor

The Small Industrial Dehydrator runs with a powerful motor. Moreover, it supports continuous operation and handles heavy drying loads efficiently.

3. Food-Grade Stainless Steel Body

This Semi Industrial Dehydrator uses stainless steel construction. In addition, it delivers strong durability, hygienic processing, and resistance to rust and corrosion.

4. Energy-Saving Thermal Insulation

The Small Industrial Dehydrator retains heat effectively. Therefore, it reduces energy loss and shortens overall drying time.

5. Wide Product Compatibility

This Semi Industrial Dehydrator processes fruits, vegetables, herbs, meat, seafood, and agricultural products. Meanwhile, it maintains reliable drying performance across different materials.

6. Simple and Precise Control Panel

The Small Industrial Dehydrator allows operators to set temperature and time easily. Finally, it improves productivity and simplifies daily operation.

CLOSER LOOK

APPLICATIONS OF SEMI INDUSTRIAL DEHYDRATOR

1. Fruit and Vegetable Processing

This Semi Industrial Dehydrator dries fruits and vegetables evenly for snacks, ingredients, and long-term storage. First, it helps producers maintain color, flavor, and nutritional value while increasing product shelf life.

2. Herb and Spice Drying

The Small Industrial Dehydrator dries herbs, spices, and medicinal plants with precise temperature control. Moreover, it preserves aroma, natural oils, and active compounds for premium-quality products.

3. Meat and Seafood Drying

This Semi Industrial Dehydrator supports the production of jerky, dried fish, and seafood products. In addition, it delivers stable drying conditions that improve texture, safety, and consistency.

4. Agricultural and Farm Production

The Small Industrial Dehydrator allows farms to process crops, fruits, and vegetables efficiently. Therefore, farmers reduce post-harvest loss and improve product value before packaging or export.

5. Commercial Kitchens and Food Workshops

This Semi Industrial Dehydrator serves restaurants, catering services, and food workshops that prepare dried ingredients daily. Finally, it increases productivity, standardizes output, and supports scalable food preparation.

HOW TO USE

- Plug the plug into the house power, turn on the switch on the back of the machine

- Place the product, arrange them together so that there is space and rows.

- Put the tray into the oven. Lay flat on the floor And close the glass door

- Press the power button on the – to start using.

- Press the Timer button to adjust the time. To use in baking by pressing the + or – button to increase and reduce the time

- Set the temperature by pressing the Temp button to enter the command and press the + or – button to increase and decrease the temperature to match the raw materials.

- Wait until the baking time expired. The device will sound an alarm when the timer expired.

- Open the cabinet to remove the product. Should be careful about the heat from the grill, should wear gloves or have heat protection equipment

- Take it out to rest to release heat from the product.

- Switch off the power button.

| Size | DH06, DH10, DH16 |

|---|

1-year manufacturing warranty.

Warranty is not applicable for the following scenarios:

- The product has abnormal shapes such as broken, chipped, bent, or missing parts

- The product has been modified, changed, or repaired by someone, other than an Automicom technician

- Improper storage such as water stains, rush marks and burn marks.

- Incorrect use overuse,

- Damaged products due to external factors such as power failure, overload, etc.

- Damaged products cause by neglect of use, and not cleaning after use.

1. What types of products can this dehydrator process?

This Semi Industrial Dehydrator dries fruits, vegetables, herbs, spices, meat, seafood, and agricultural products. It supports consistent drying for both food processing and farm production.

2. How does this dehydrator ensure even drying results?

The Small Industrial Dehydrator uses a hot-air circulation system that distributes heat evenly across all 32 trays. As a result, operators achieve uniform moisture removal and stable product quality.

3. Is this dehydrator easy to operate and maintain?

This Semi Industrial Dehydrator features a simple control panel for temperature and time adjustment. The stainless steel structure allows quick cleaning and supports long-term daily operation.

Automatic Cup Sealer (CS600)

Automatic Cup Sealer (CS600)

Reviews

There are no reviews yet.