No products in the cart.

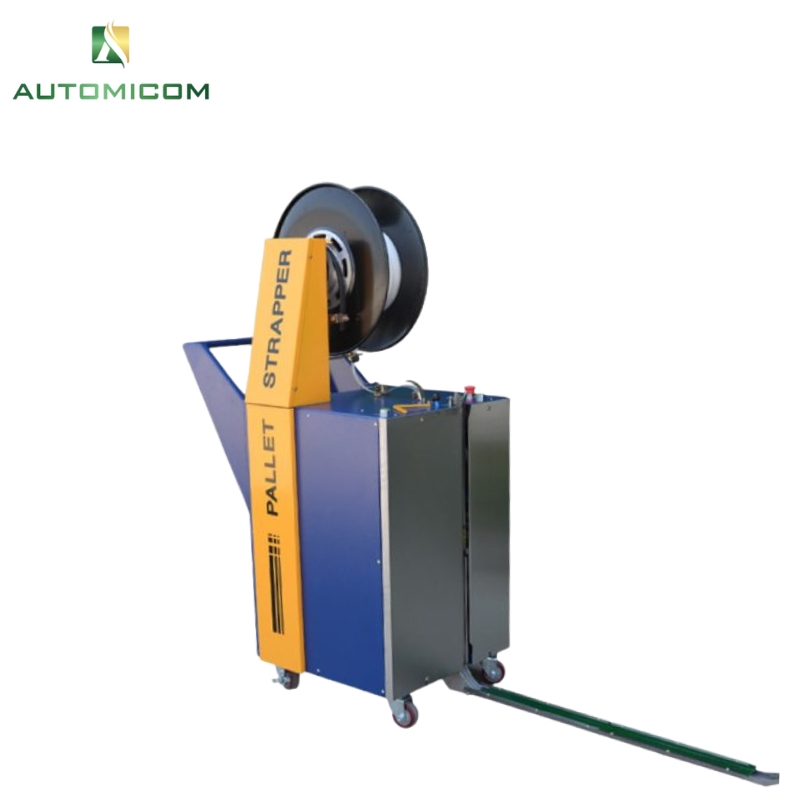

Pallet Strapping Machine (PS130A)

$5,500.00

- Fast Load Securing ensures pallets stay stable during transport and storage.

- Versatile Size Handling fits multiple pallet dimensions and material types.

- High-Speed Operation reaches up to 30 efficient cycles per minute.

- Flexible Packing Options allow continual or precise sequence strapping patterns.

- Easy Mobility moves smoothly using four strong and durable wheels.

PALLET STRAPPING MACHINE (PS130A)

INTRODUCTION OF PALLET STRAPPING MACHINE

A Pallet Strapping Machine gives businesses the speed, safety, and efficiency they need to secure goods on pallets. It applies strong straps around palletized loads, holding products firmly during handling, storage, and transport. By using a Pallet Strapping Machine, companies boost packaging speed, cut labor costs, and maintain consistent strap tension for maximum load safety.

The Pallet Securing Machine works across many industries, including logistics, warehousing, manufacturing, and distribution. It handles a wide range of pallet sizes and materials, so operators can bundle boxes, cartons, or even irregularly shaped items with ease. In addition, automated or semi-automatic options let teams maintain product integrity while preventing damage from shifting during transit.

Moreover, the Pallet Strapping Machine and the Pallet Securing Machine feature durable components that withstand heavy use. As a result, they improve operational efficiency, protect valuable goods, and keep the supply chain moving smoothly. Ultimately, businesses that adopt these machines secure a reliable, fast, and cost-effective packaging solution that adapts to their specific needs.

SPECIFICATIONS

| Model | PS130A |

| Strapping tension | 100-600N adjustable |

| Strapping speed | 2.0Sec./Strap |

| Strap width | 9-15mm |

| Chute size | L1000mm |

| Power supply | 110,220V/50-60Hz |

| Power consumption | 0.5KVA |

| Machine size | 1860 x 560 x 1500mm |

| Machine weight | 140kg |

KEY FEATURES OF PALLET STRAPPING MACHINE

High-Quality Components

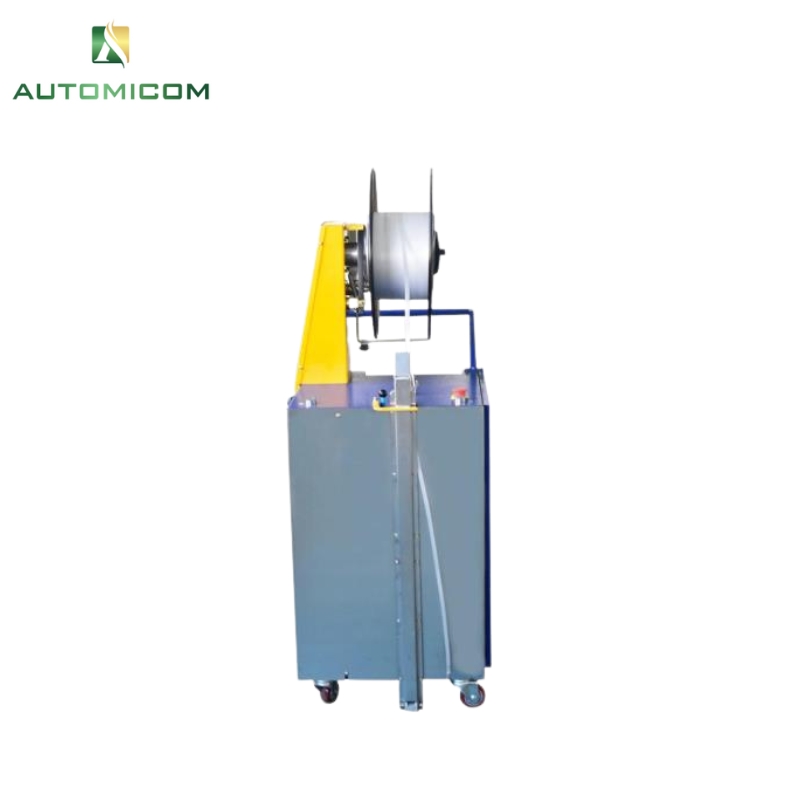

The Pallet Strapping Machine and Pallet Securing Machine use premium components from TE, Omron (Japan), and ZIK. These trusted brands ensure stable performance, improve safety, and extend service life, even in demanding production environments.User-Friendly Design

Operators load strapping rolls quickly through the external dispenser, which saves time and improves workflow. Smooth strap feeding and controls like the DBA-130A’s ball switch and foot pedal let operators work faster and with greater comfort.Flexible Packing Options

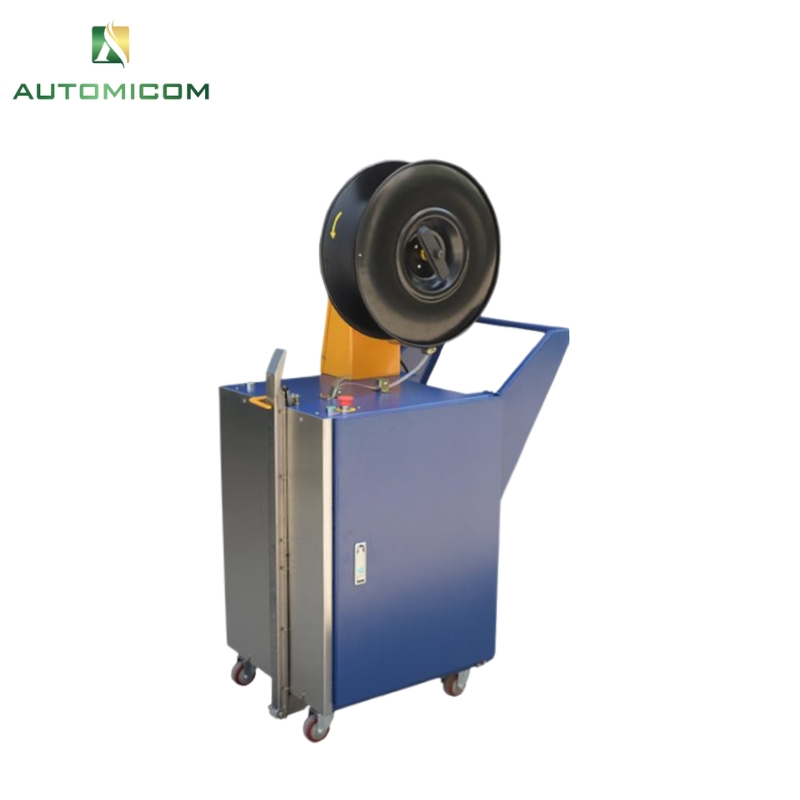

These machines handle parallel strapping from one to several strips. In addition, continual packing boosts speed, while sequence packing ensures precise patterns for specific load requirements.

Rapid Strapping Speed

Each cycle takes just 2 seconds and reaches up to 30 cycles per minute. As a result, the machines keep pace with high-volume operations and reduce production delays.Smart PLC Control

The integrated LG PLC enables accurate tension settings and reliable automation. Moreover, quick adjustments help operators maintain consistency and avoid errors.Versatile Mobility

Four durable wheels allow easy movement between workstations, which streamlines layout changes and keeps warehouse operations running smoothly

CLOSER LOOK

APPLICATIONS OF PALLET STRAPPING MACHINE

Logistics and Freight Handling

Firstly, the Pallet Strapping Machine and Pallet Securing Machine secure palletized goods for truck, ship, or air freight, ensuring loads stay stable and undamaged during long-distance shipping.Warehouse Storage

Secondly, businesses strap and stabilize goods on pallets for safe stacking in storage areas. In addition, this process prevents product shifting and maximizes available space.Manufacturing and Assembly Lines

Thirdly, Operators bundle finished products directly on the production floor. As a result, handling time decreases, and workflow between production stages stays smooth.Retail and Distribution Centers

Fourthly, Teams prepare bulk shipments for delivery to retail outlets or customers. Moreover, this approach keeps orders organized and intact throughout the supply chain.Food and Beverage Packaging

Finally, companies protect packaged food products, beverage cases, and other sensitive items on pallets. Furthermore, consistent strapping maintains product quality from plant to market.

FINDING MORE STRAPPING MACHINE HERE: LINK

1 year warranty

1. What types of pallets can this machine strap?

It handles a wide range of pallet sizes and materials, including wood, plastic, and metal pallets, as well as irregularly shaped loads.

2. How fast can the machine strap a pallet?

With a cycle time of just 2 seconds per strap and up to 30 cycles per minute, it keeps up with high-volume operations.

3. Is the machine easy to move between workstations?

Yes. Four durable wheels allow operators to reposition it effortlessly, making it ideal for dynamic warehouse or production layouts.

4. Can the machine work with different strapping methods?

Absolutely. It supports parallel strapping from one to several strips, continual packing for speed, and sequence packing for precise patterns.